Introduction

In today’s global marketplace, consumers expect the products they purchase to meet high standards of quality, safety, and reliability. Whether it’s electronics, food, pharmaceuticals, or automobiles, consumers want assurance that the products they buy will perform as expected and won’t pose any risks to their health or safety. This is where product testing and compliance come into play, playing a vital role in ensuring that products meet regulatory requirements and industry standards.

Product testing and compliance are the cornerstones of consumer protection and trust. They serve as a safeguard against substandard or potentially hazardous products, giving consumers confidence in their choices. Additionally, they provide a level playing field for businesses, ensuring fair competition based on product quality and safety rather than cutting corners. In a world where products are constantly evolving, and markets are increasingly competitive, the role of product testing and compliance becomes even more critical. It’s a dynamic field that adapts to emerging technologies and new challenges, ultimately serving the best interests of both consumers and responsible businesses.

For a comprehensive look at this subject, we invite you to read more on this dedicated page: What is a Quality Management System (QMS)? | ASQ

Product testing is the process of evaluating and verifying that a product meets specified requirements and standards. It involves subjecting the product to various tests and assessments to determine its quality, safety, and performance. Product testing serves several essential purposes:

Product testing is a multifaceted process with far-reaching implications for product quality, safety, and consumer satisfaction. Here’s an in-depth exploration of why product testing is indispensable in today’s market:

Quality Assurance: At its core, product testing is about ensuring that a product functions as intended and meets the quality standards set by the manufacturer. Rigorous testing identifies defects, malfunctions, or inconsistencies that might compromise a product’s overall quality. By rectifying these issues early in the development process, manufacturers can prevent costly recalls and reputational damage.

Safety Validation: Perhaps the most critical aspect of product testing is safety validation. Consumers rely on products for their well-being, and any safety-related issues can have severe consequences. Through testing, potential safety hazards are identified and mitigated, guaranteeing that products won’t harm users when used as intended.

Compliance with Standards: In many industries, products must adhere to specific standards and regulations to ensure their safety and performance. Product testing serves as the means to demonstrate compliance with these standards, facilitating market access and regulatory approval. Non-compliance can lead to legal consequences and market exclusion.

Performance Optimization: Beyond meeting basic quality and safety requirements, product testing helps optimize performance. It assesses how well a product functions under various conditions, offering insights into potential improvements. By refining performance, manufacturers can gain a competitive edge in the market.

Enhanced Reliability: Product testing is instrumental in enhancing product reliability. It simulates real-world scenarios, stress-testing products to their limits. By identifying weak points and addressing them, manufacturers can create products that are more reliable and less prone to failures or breakdowns.

Consumer Confidence: In an era of heightened consumer awareness, trust is paramount. Product testing bolsters consumer confidence by providing assurance that products have been rigorously evaluated for quality and safety. This trust can translate into brand loyalty and positive reviews, driving sales and market share.

Innovation and Development: Testing isn’t limited to existing products; it plays a crucial role in innovation and development. New product prototypes undergo testing to validate concepts and identify potential issues early, streamlining the product development process.

Cost Reduction: While product testing requires an initial investment, it can ultimately save manufacturers money in the long run. Identifying and rectifying issues during the testing phase is far more cost-effective than dealing with product recalls, legal liabilities, and customer compensation in the event of safety or quality problems.

Market Differentiation: In crowded markets, product testing can be a means of differentiation. Products that boast comprehensive testing and superior safety records stand out, attracting consumers who prioritize quality and safety over price alone.

Regulatory Compliance: Many industries are heavily regulated, and adherence to these regulations is non-negotiable. Product testing provides the evidence required to satisfy regulatory authorities, ensuring that products can be legally marketed and sold.

Environmental Impact: In an increasingly eco-conscious world, product testing can also encompass environmental considerations. Assessing a product’s environmental impact, such as its energy efficiency or recyclability, can help manufacturers meet sustainability goals and appeal to environmentally conscious consumers.

Continuous Improvement: Product testing isn’t a one-time affair; it’s a continuous process that fosters a culture of improvement. Manufacturers who embrace ongoing testing are better positioned to refine existing products and innovate for the future.

In summary, product testing is the linchpin of quality, safety, and innovation in the modern marketplace. It’s a proactive measure that safeguards consumers, builds trust, ensures compliance, and ultimately contributes to the success and sustainability of businesses in an ever-evolving competitive landscape.

Looking for more insights? You’ll find them right here in our extended coverage: Quality Control: What It Is, How It Works, and QC Careers

Product testing helps manufacturers identify defects or quality issues in their products before they reach consumers. This ensures that consumers receive products that meet their expectations and perform as intended.

Product Testing: The Guardian of Quality and Safety

In the dynamic world of product manufacturing, where innovation and efficiency reign supreme, ensuring the quality and safety of products is paramount. Product testing emerges as the steadfast sentinel, tirelessly working behind the scenes to guarantee that items hitting the market meet not only regulatory standards but also the lofty expectations of consumers.

Quality Assurance Through Rigorous Testing

Product testing encompasses a broad spectrum of evaluations, examinations, and analyses, all with a singular objective: to verify that a product functions as intended and adheres to the highest quality standards. It’s a meticulous process that scrutinizes every facet, from design and materials to functionality and durability.

Identifying Defects Before They Surface

One of the primary roles of product testing is defect identification. Manufacturers rely on various testing methods to uncover flaws and imperfections that could compromise a product’s performance or safety. This proactive approach allows for early intervention and correction, preventing defective products from ever reaching the hands of consumers.

Meeting Regulatory Standards

In many industries, regulatory compliance is not just a goal but a legal requirement. Product testing serves as the litmus test for adherence to these regulations. By subjecting products to a battery of tests and assessments, manufacturers can ensure that their offerings meet the stringent criteria set forth by governing bodies.

Consumer Confidence and Satisfaction

Beyond regulatory compliance, product testing is a linchpin in building and maintaining consumer trust. When consumers purchase a product, they expect it to deliver on its promises. Product testing is the assurance they need that their hard-earned money is well spent and that the product they bring home will perform reliably and safely.

Diverse Approaches for Diverse Products

Product testing isn’t a one-size-fits-all endeavor. Different types of products demand different testing methods. For instance, a pharmaceutical product undergoes rigorous clinical trials, while a new automobile model endures a battery of crash tests and performance evaluations. Each product category requires tailored testing procedures to address its unique characteristics and potential risks.

Beyond Functionality: Ensuring Safety and Compliance

In addition to functionality, product testing extends its reach to encompass safety and compliance with industry-specific standards. This is particularly vital in fields where product failure can have dire consequences, such as healthcare, aerospace, and automotive industries.

The Role of Innovation in Testing

As technology advances, so too does the sophistication of product testing. Cutting-edge techniques like non-destructive testing, simulation testing, and accelerated aging tests push the boundaries of what’s possible. These innovative methods not only enhance the accuracy and efficiency of testing but also drive product innovation, allowing manufacturers to create safer, more durable, and more efficient products.

In conclusion, product testing stands as a sentinel guarding the gateway to the consumer market. Its multifaceted role encompasses quality assurance, defect detection, regulatory compliance, and consumer satisfaction. In an era where product excellence is not just an aspiration but an expectation, product testing remains an indispensable tool for manufacturers striving to meet and exceed those expectations.

For additional details, consider exploring the related content available here Beverage Testing: From Quality Control to Compliance Issues

Safety is a paramount concern across various industries, including automotive, healthcare, and food. Product testing helps identify potential safety hazards and ensures that products meet safety standards, reducing the risk of harm to consumers.

Safety is of paramount importance in a multitude of industries, from automotive and healthcare to food production. Product testing plays a pivotal role in the pursuit of safety, as it identifies potential hazards and verifies that products adhere to rigorous safety standards. By subjecting items to comprehensive testing procedures, businesses and manufacturers can significantly reduce the risk of harm to consumers. Whether it’s crash tests for automobiles, quality checks for medical devices, or food safety assessments, the practice of rigorous product testing ultimately fosters trust, protects public well-being, and upholds industry integrity.

To expand your knowledge on this subject, make sure to read on at this location: Product Quality & Safety | The Coca-Cola Company

Regulatory bodies and industry associations often establish specific standards and requirements that products must meet. Product testing is essential for verifying compliance with these standards, helping companies avoid legal issues and costly recalls.

“Compliance with industry-specific standards and regulations is critical for businesses. These standards, often set by regulatory bodies and industry associations, dictate the requirements products must meet. Rigorous product testing is vital to ensure adherence to these standards, safeguarding companies from legal complications and expensive product recalls.”

To delve further into this matter, we encourage you to check out the additional resources provided here: Beverage Testing: From Quality Control to Compliance Issues

Product testing isn’t just about meeting minimum requirements; it also drives innovation. By continually testing and improving their products, companies can stay ahead of the competition and meet evolving consumer demands.

Product testing is a dynamic process that goes beyond mere compliance with minimum requirements; it serves as a catalyst for innovation. Forward-thinking companies recognize that by consistently subjecting their products to rigorous testing and assessment, they can not only ensure quality and safety but also pioneer new advancements in their respective industries. This commitment to innovation allows them to proactively respond to changing consumer preferences and market trends, ultimately positioning themselves as industry leaders and staying one step ahead of their competitors. In a rapidly evolving marketplace, the synergy between product testing and innovation is a powerful driver of success.

Additionally, you can find further information on this topic by visiting this page: Product Quality & Safety | The Coca-Cola Company

Product testing can encompass various types, depending on the industry and the nature of the product. Here are some common types of product testing:

Certainly, here are some common types of product testing:

Functional Testing: This evaluates whether the product performs its intended functions correctly and efficiently.

Safety Testing: Ensures that the product does not pose any harm or danger to users when used as intended.

Usability Testing: Focuses on the product’s user-friendliness, including user interface and overall user experience.

Reliability Testing: Determines the product’s consistency and durability over time, assessing its longevity and robustness.

Compatibility Testing: Checks if the product works seamlessly with other devices, systems, or software.

Performance Testing: Measures the product’s speed, responsiveness, and efficiency under various conditions.

Quality Assurance Testing: Encompasses a comprehensive evaluation of the product to ensure it meets established quality standards.

Compliance Testing: Ensures the product adheres to industry-specific regulations and standards.

Alpha and Beta Testing: Involves testing by a select group of users (alpha) and a larger group (beta) to identify issues and gather user feedback.

Environmental Testing: Evaluates how the product performs under different environmental conditions, such as temperature and humidity.

These various types of product testing collectively contribute to ensuring the quality, safety, and reliability of products across diverse industries.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Product Quality and Safety | Mattel, Inc.

This type of testing evaluates how well a product performs under different conditions. For example, performance testing of a car might include assessments of acceleration, braking, and fuel efficiency.

Performance testing is an essential aspect of product evaluation, ensuring that it meets expectations and functions optimally. Whether it’s a vehicle’s acceleration and braking or a software application’s responsiveness and scalability, these tests provide valuable insights into how products perform in real-world scenarios. By subjecting products to various conditions and stress levels, manufacturers can identify weaknesses, make improvements, and deliver higher quality and more reliable offerings to consumers.

To expand your knowledge on this subject, make sure to read on at this location: Footwear Laboratory Testing for Safety & Performance | QIMA – QIMA

Durability testing assesses a product’s ability to withstand wear and tear over time. This is crucial for products like electronics, appliances, and industrial machinery.

Durability testing goes beyond just assessing a product’s ability to withstand wear and tear; it’s about ensuring that a product can maintain its performance and safety characteristics throughout its expected lifespan. For consumer electronics, this means evaluating how well a smartphone or laptop can endure daily use without compromising functionality. In the automotive industry, durability testing involves subjecting vehicles to extreme conditions, simulating years of wear on their components to ensure they remain safe and reliable. The goal is not just to meet minimum standards but to exceed them, providing consumers with products that deliver long-term value and peace of mind. Durability testing is a testament to a manufacturer’s commitment to quality and their dedication to producing products that stand the test of time.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Key Aspects of Textile Testing for Manufacturers | QIMA – QIMA

Safety testing ensures that a product doesn’t pose any risks to consumers. This includes tests for electrical safety, flammability, and toxicity.

Safety testing is a critical aspect of product evaluation, encompassing a range of assessments to guarantee consumer well-being. This includes rigorous examinations for electrical safety to prevent potential hazards, assessments of flammability to mitigate fire risks, and tests for toxicity to ensure products are free from harmful substances. By conducting comprehensive safety testing, manufacturers and regulatory bodies can provide consumers with peace of mind and confidence in the products they use.

Should you desire more in-depth information, it’s available for your perusal on this page: Beverage Testing: From Quality Control to Compliance Issues

Reliability testing assesses a product’s ability to function consistently without failures. This is vital for critical systems like medical devices and aerospace components.

Reliability Testing: The Crucible of Endurance

In the realm of product testing, where quality and dependability are of paramount importance, reliability testing emerges as a crucible of endurance. It’s the rigorous evaluation that separates the merely functional from the truly dependable, making it especially critical in industries where lives and safety are on the line.

Unwavering Performance in Critical Systems

Reliability testing zeroes in on one pivotal question: Can this product be trusted to perform consistently, without fail, over an extended period? The answer to this question is crucial for products that find homes in critical systems where failure is not an option.

Medical Devices: A Matter of Life and Death

Consider the realm of medical devices, where reliability testing is a matter of life and death. From pacemakers that regulate heart rhythms to diagnostic equipment that provides vital information, these devices must function flawlessly. Reliability testing simulates the stresses and conditions these devices will encounter in real-world use, ensuring that they perform consistently and without interruption.

Aerospace: Safety Above All Else

In the aerospace industry, where human lives are at stake with every flight, reliability takes on a new dimension of importance. Components like engines, avionics, and control systems undergo exhaustive testing to ensure they withstand the harsh conditions of space and flight. Reliability testing is the assurance that every part of the aircraft will perform reliably, even in the harshest environments.

Pushing the Limits of Endurance

Reliability testing goes beyond the ordinary. It subjects products to extreme conditions, intense stress, and prolonged usage to see how they hold up. It’s a test of resilience, a measure of a product’s ability to endure the harshest circumstances and continue functioning without compromise.

Environmental Stress Testing

Part of reliability testing involves environmental stress testing. This includes exposing products to extremes of temperature, humidity, vibration, and shock to mimic the challenges they might face in the field. This testing reveals weaknesses, vulnerabilities, and areas for improvement.

Failure Analysis: Learning from Defects

When products do fail during reliability testing, it’s not seen as a setback but as an opportunity to learn and enhance. Failure analysis delves into the root causes of failure, enabling engineers to refine designs, materials, and manufacturing processes.

Beyond Safety: Building Trust

Reliability testing serves a dual purpose. While it ensures safety and performance, it also builds trust. When a product passes rigorous reliability tests, it instills confidence in both manufacturers and end-users. It’s a testament that the product has been scrutinized under the harshest conditions and has emerged unscathed.

Innovation and Continuous Improvement

In the ever-evolving landscape of technology and engineering, reliability testing continually pushes the envelope. Innovations in testing methodologies, such as accelerated life testing and predictive modeling, allow engineers to predict a product’s reliability with increasing accuracy, guiding design and manufacturing improvements.

In conclusion, reliability testing stands as the sentinel of trust and dependability in product manufacturing. It ensures that products meet the stringent demands of industries where failure is not an option. From healthcare to aerospace, it plays a pivotal role in safeguarding lives and enhancing safety while driving innovation and continuous improvement in the relentless pursuit of excellence.

To expand your knowledge on this subject, make sure to read on at this location: Why Product Testing is Crucial for Ensuring Quality and Safety

Environmental testing evaluates a product’s performance under various environmental conditions, such as temperature, humidity, and altitude. It’s crucial for products used in diverse climates and locations.

Environmental testing is a critical facet of product evaluation, as it assesses how a product performs under a spectrum of environmental conditions. These conditions can encompass extreme temperatures, varying humidity levels, high altitudes, and exposure to environmental factors like saltwater or dust. Such testing is especially vital for products intended for use in diverse climates and geographical locations. Whether it’s testing the durability of electronic devices in arctic temperatures or evaluating the resilience of construction materials in tropical humidity, environmental testing ensures that products maintain their functionality and reliability across a range of real-world scenarios. This thorough assessment not only enhances product quality but also bolsters consumer confidence in their durability and performance, regardless of where they are used.

Additionally, you can find further information on this topic by visiting this page: Product Quality & Safety | The Coca-Cola Company

Some industries, like pharmaceuticals and food, are heavily regulated. Regulatory compliance testing ensures that products meet all legal requirements and quality standards.

“Industries such as pharmaceuticals and food are subject to extensive regulation due to their impact on public health and safety. Regulatory compliance testing is essential in these sectors to verify that products not only meet legal requirements but also adhere to stringent quality standards, safeguarding consumers and businesses alike.”

You can also read more about this here: Beverage Testing: From Quality Control to Compliance Issues

Compliance is a critical aspect of product testing. Compliance involves adhering to specific regulations, industry standards, and quality requirements applicable to a product. Non-compliance can lead to legal issues, product recalls, and damage to a company’s reputation.

Companies must navigate a complex landscape of regulations, which can vary by region and product type. Regulatory compliance often involves product labeling, safety certifications, and documentation of the testing and validation processes. Working with regulatory experts and staying informed about changes in regulations is crucial for ensuring compliance.

Compliance stands as a foundational pillar in the realm of product testing, encompassing a comprehensive array of considerations. At its core, compliance hinges on a company’s unwavering commitment to adhering to a web of regulations, industry standards, and stringent quality prerequisites that pertain to their specific product. Deviating from these prescribed norms can have profound consequences, potentially triggering a cascade of legal issues, costly product recalls, and a tarnished corporate reputation.

In the modern global marketplace, navigating the intricate terrain of regulations is akin to embarking on a labyrinthine journey. The rules that govern vary significantly not only from one region to another but also from one product category to the next. Achieving regulatory compliance often entails a multifaceted approach that spans from meticulous product labeling and obtaining safety certifications to diligently documenting the testing and validation processes.

Recognizing the complexity of the compliance landscape, companies must bolster their efforts through collaboration with regulatory experts. These experts possess the specialized knowledge required to decipher the intricate legal frameworks and ensure that products meet all relevant requirements. Moreover, staying vigilant and proactive in monitoring changes in regulations is non-negotiable. As regulations evolve over time, businesses must remain adaptable and responsive to ensure ongoing compliance, safeguard consumer safety, and fortify their brand’s integrity in the market.

For additional details, consider exploring the related content available here Position on quality, safety and compliance – A new view of care

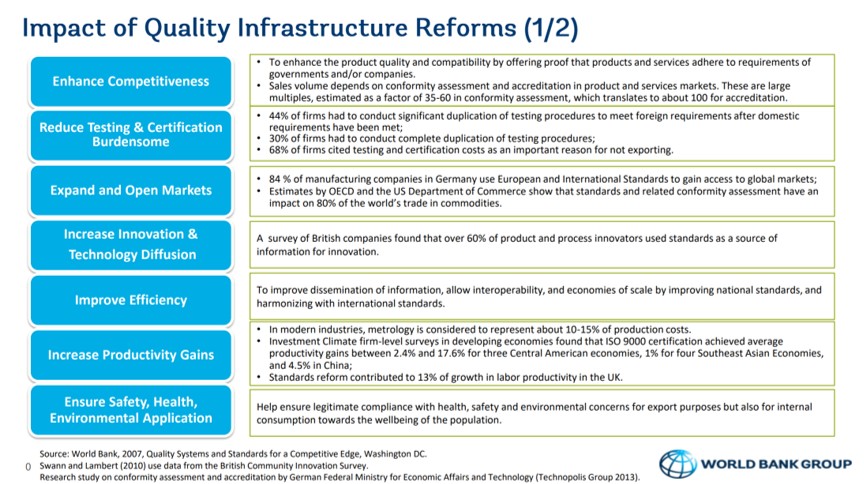

Product testing doesn’t just ensure compliance and safety; it also drives innovation. Companies that invest in research and development and robust testing processes can create products that outperform competitors and meet the evolving needs of consumers. Innovation in product testing methodologies, such as the use of artificial intelligence and predictive analytics, is also on the rise, allowing companies to identify issues earlier in the development process.

Indeed, product testing is a powerful driver of innovation in various industries. Here’s how it fosters innovation:

Enhanced Product Quality: Rigorous testing processes help identify and rectify quality issues early in product development. This leads to products with fewer defects, improving overall quality.

Consumer-Centric Design: Through testing, companies gain valuable insights into consumer preferences and pain points. This feedback informs product design, resulting in offerings that better meet customer needs and expectations.

Competitive Edge: Innovations in testing can lead to the development of unique features or functionalities that set products apart from competitors. This can be a significant competitive advantage.

Efficiency Improvements: Testing methodologies that leverage automation, artificial intelligence, and data analytics streamline the testing process. This efficiency allows for quicker product development and time-to-market.

Risk Mitigation: Identifying and addressing potential issues early minimizes the risk of costly recalls or product failures post-launch. This saves both money and reputation.

Environmental Considerations: Sustainable product testing methods promote eco-friendly product design, aligning with the growing demand for environmentally responsible offerings.

Regulatory Compliance: Staying ahead of evolving regulations requires innovative testing approaches. Companies that proactively meet or exceed compliance standards are better positioned for success.

Continuous Improvement: Ongoing product testing encourages a culture of continuous improvement within organizations. This mindset fosters innovation at every stage of product development.

Customization: Tailoring testing protocols to specific product requirements allows for greater customization. This can result in products that precisely address niche markets or customer segments.

In essence, product testing is not just a compliance necessity; it’s a strategic tool for driving innovation, improving product quality, and meeting the ever-changing demands of consumers and markets. As technology and methodologies continue to advance, the role of product testing in innovation will only become more prominent.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Product Evaluation and Testing – ICC

Conclusion

Product testing and compliance are fundamental to the modern economy, ensuring that products meet quality, safety, and regulatory standards. From automobiles to pharmaceuticals, consumers rely on product testing to make informed choices and trust the products they purchase. In a world where innovation and safety go hand in hand, product testing plays a pivotal role in driving progress and ensuring that the products we use are of the highest quality.

In our ever-evolving world, the symbiotic relationship between innovation and safety is more critical than ever. Product testing and compliance stand as the guardians of this delicate balance, assuring consumers that the products they choose are not only innovative but also adhere to the highest quality, safety, and regulatory standards. Whether it’s the rigorous testing of cutting-edge automotive technologies to ensure road safety or the meticulous evaluation of pharmaceuticals for efficacy and safety, these practices instill confidence in consumers. They empower individuals to make informed choices, enrich their lives with the latest advancements, and trust that their well-being is safeguarded. In essence, product testing and compliance are the cornerstones of progress, shaping a world where innovation and safety are not opposing forces but harmonious partners in advancing our quality of life.

You can also read more about this here: Facts About the Current Good Manufacturing Practices (CGMP) | FDA

More links

Additionally, you can find further information on this topic by visiting this page: Beverage Testing: From Quality Control to Compliance Issues