Introduction

In today’s interconnected global economy, supply chains are the lifelines of businesses, ensuring the flow of goods and services from manufacturers to consumers. However, these intricate networks are susceptible to a myriad of risks that can disrupt operations and impact profitability. To navigate this complex landscape, organizations must prioritize supply chain resilience and effective risk management.

In an era where the world’s economies are intricately intertwined, supply chains emerge as the vital arteries that sustain the lifeblood of businesses. These intricate networks facilitate the seamless flow of goods and services, linking manufacturers to consumers across vast distances. However, the very complexity that makes supply chains so powerful also renders them susceptible to an array of risks, lurking like shadows ready to disrupt operations and undermine profitability.

The global supply chain landscape is a tapestry woven with threads of complexity. It spans continents, encompassing suppliers, manufacturers, distributors, and retailers, each playing a crucial role in delivering products to consumers’ doorsteps. Along this journey, supply chains encounter a multitude of potential hazards, from natural disasters and geopolitical conflicts to economic volatility and cybersecurity threats.

Natural disasters, such as earthquakes, hurricanes, and floods, can cripple critical nodes within a supply chain. Factories may be damaged, transportation routes blocked, and warehouses flooded, causing delays in production and delivery. These disruptions not only affect the bottom line but also erode customer trust and brand reputation.

Geopolitical tensions and trade disputes can introduce an element of uncertainty into supply chains. Tariffs, trade restrictions, and political instability can disrupt the free flow of goods and lead to sudden shifts in procurement strategies. For organizations heavily reliant on international suppliers, navigating this terrain demands adaptability and contingency planning.

Economic volatility, including currency fluctuations and inflation, can impact supply chain costs and pricing strategies. A sudden spike in raw material prices or a currency devaluation in a key market can throw carefully calibrated supply chains into disarray, prompting the need for rapid cost adjustments.

The digital age has ushered in a new frontier of risks, with cybersecurity threats lurking in the digital shadows. Hackers targeting supply chain systems can not only compromise sensitive data but also disrupt operations by taking control of critical infrastructure or disrupting communications. The fallout from a cybersecurity breach can be devastating, both in financial terms and in terms of customer trust.

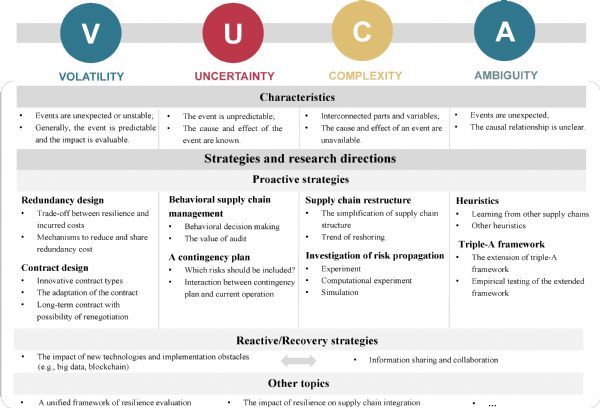

To thrive in this dynamic landscape, organizations must adopt a proactive approach to supply chain resilience and risk management. This involves a multi-faceted strategy that encompasses risk assessment, contingency planning, and the development of agile supply chain models.

Risk assessment begins with a thorough understanding of the supply chain’s vulnerabilities. This includes identifying critical nodes, evaluating the impact of potential risks, and quantifying the potential financial losses associated with disruptions. Armed with this knowledge, organizations can develop risk mitigation strategies tailored to their unique circumstances.

Contingency planning involves the development of response plans for various scenarios, from natural disasters to geopolitical upheavals. These plans outline the steps to be taken in the event of a disruption, ensuring that employees know how to react and enabling the organization to minimize downtime and financial losses.

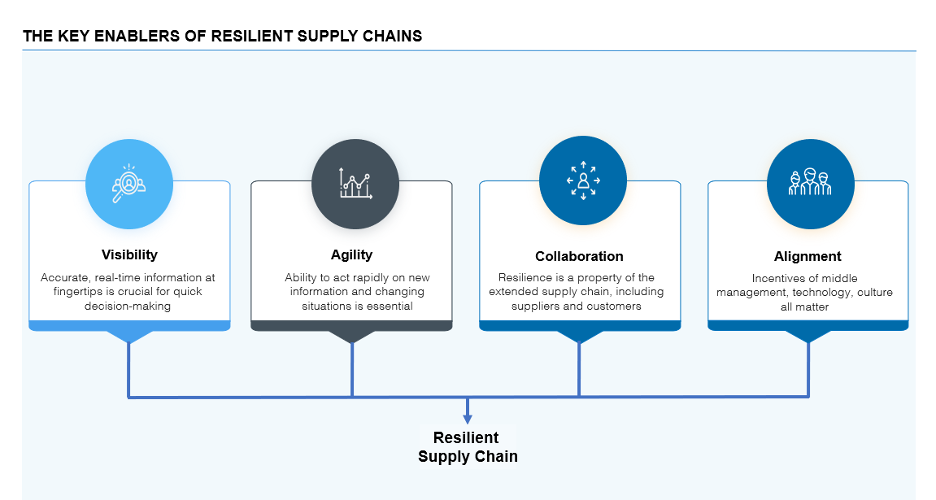

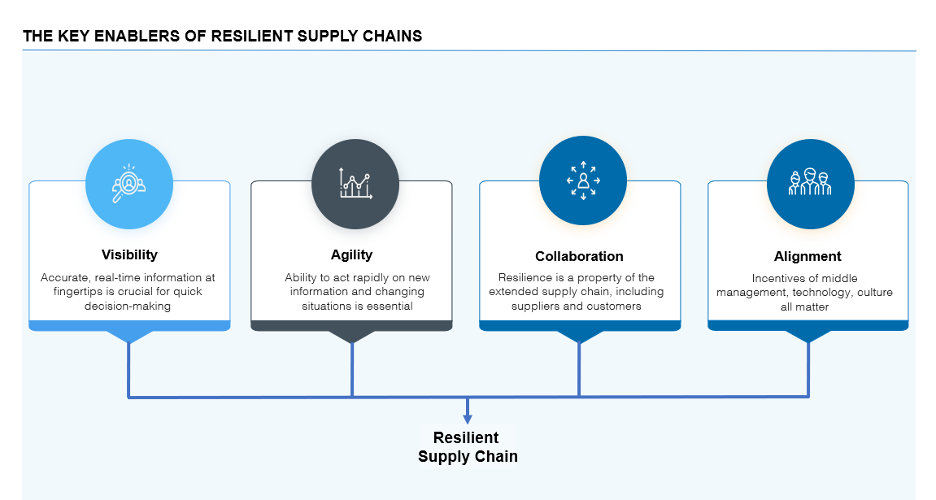

Agility is perhaps the linchpin of supply chain resilience. Organizations that can swiftly adapt to changing circumstances, whether through diversifying suppliers, implementing real-time monitoring systems, or leveraging advanced analytics, are better positioned to weather disruptions and maintain a competitive edge.

In conclusion, supply chain resilience and effective risk management are not just buzzwords; they are prerequisites for survival in today’s globalized economy. Organizations that prioritize these principles understand that the ability to anticipate, adapt, and mitigate risks is the key to maintaining the lifelines of their businesses, ensuring continuity, and safeguarding their reputation in an unpredictable world.

To expand your knowledge on this subject, make sure to read on at this location: Supply Chain Resilience Guide | FEMA

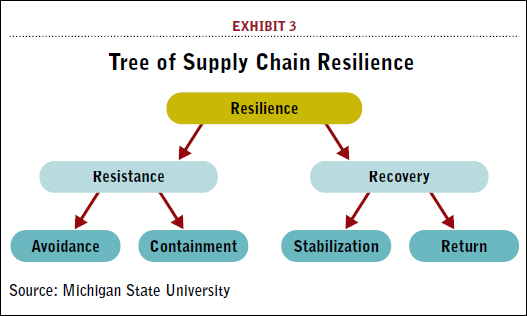

Supply chain resilience refers to an organization’s ability to withstand and recover from disruptions while maintaining essential functions. It involves identifying vulnerabilities, implementing strategies to mitigate risks, and ensuring business continuity even in the face of adverse events.

Supply chain resilience is a fundamental concept in modern business operations, encompassing a range of strategies and practices aimed at fortifying an organization’s capacity to navigate and rebound from disruptions effectively. Here are several key aspects of supply chain resilience:

Risk Assessment and Vulnerability Identification: A resilient supply chain begins with a comprehensive assessment of potential risks and vulnerabilities. This involves analyzing the entire supply network, from suppliers to distribution channels. Identifying weak points, dependencies, and potential disruptions, such as natural disasters, geopolitical issues, or supply chain bottlenecks, is crucial.

Diverse Supplier Base: Relying on a diverse supplier base can enhance resilience. If a single supplier faces disruptions, having alternatives in place can ensure a continued flow of critical inputs. This diversity can also include sourcing from multiple geographic regions to reduce exposure to localized risks.

Inventory and Buffer Stocks: Maintaining adequate inventory levels and buffer stocks can serve as a cushion during disruptions. While reducing inventory is often seen as a cost-saving measure, having strategic reserves of key components or finished products can provide a critical buffer during times of supply chain stress.

Demand Forecasting and Communication: Accurate demand forecasting is vital for supply chain resilience. By understanding customer needs and preferences, organizations can adjust their production and distribution strategies accordingly. Effective communication with customers, suppliers, and stakeholders is also crucial during disruptions to manage expectations and coordinate responses.

Technology and Data Analytics: Leveraging technology, including data analytics and real-time monitoring, allows organizations to gain visibility into their supply chains. Advanced analytics can identify potential disruptions early, enabling proactive responses. Technologies like the Internet of Things (IoT) can provide real-time data on the status of goods in transit.

Supplier Relationships and Collaboration: Building strong relationships with suppliers is integral to resilience. Collaborative partnerships can facilitate information sharing, joint risk assessment, and coordinated responses to disruptions. Trust and open communication with suppliers can lead to mutually beneficial solutions during crises.

Scenario Planning and Contingency Plans: Developing scenario-based contingency plans is a hallmark of a resilient supply chain. Organizations can simulate various disruption scenarios and plan their responses accordingly. This proactive approach helps reduce the time it takes to recover from unexpected events.

Diversified Transportation Modes: Relying on multiple transportation modes, such as rail, road, air, and sea, can add flexibility to the supply chain. This diversification ensures that disruptions in one mode can often be mitigated by shifting to another, depending on the nature of the disruption.

Employee Training and Skill Development: Human resources are a critical component of supply chain resilience. Training employees in crisis management, problem-solving, and adaptability can ensure a coordinated and effective response when disruptions occur.

Continuous Improvement: Resilience is an ongoing process that requires continuous improvement. Regularly reviewing and updating risk assessments, contingency plans, and supply chain strategies is essential to adapt to changing circumstances and emerging threats.

In today’s interconnected global economy, supply chain resilience is not just a competitive advantage; it is a necessity. Organizations that prioritize resilience are better positioned to protect their operations, maintain customer trust, and ensure business continuity in the face of unforeseen challenges.

To delve further into this matter, we encourage you to check out the additional resources provided here: Understanding Supply Chain Resilience – Supply Chain 24/7

While globalization has expanded markets and opportunities, it has also increased supply chain complexity. Organizations often source components and products from various regions, making them vulnerable to international disruptions such as political conflicts, trade disputes, and natural disasters.

The era of globalization has undeniably ushered in an era of unprecedented opportunities and connectivity for businesses worldwide. It has paved the way for the expansion of markets, the diversification of product offerings, and the streamlining of production processes. However, amid these significant advantages, globalization has also introduced a new level of complexity to supply chains that organizations must navigate.

One of the central facets of this complexity is the intricate web of global supply chains. Organizations now source components, raw materials, and finished products from a multitude of regions across the globe. While this diversification can optimize costs and improve resource utilization, it also exposes businesses to an array of international disruptions, both anticipated and unforeseen.

Political conflicts, a perennial challenge on the global stage, can significantly impact the reliability of supply chains. Trade disputes, tariff escalations, or economic sanctions between nations can disrupt the flow of goods and materials, leading to delays, increased costs, and market uncertainty. Organizations must remain agile and adaptable to swiftly respond to such geopolitical developments.

Natural disasters, ranging from earthquakes and hurricanes to droughts and pandemics, are another formidable threat to the global supply chain. These events can disrupt manufacturing facilities, transportation networks, and logistics hubs, causing production slowdowns and shortages. As climate change accelerates, the frequency and severity of these events may further intensify, underscoring the importance of robust supply chain resilience.

The COVID-19 pandemic, a recent and profound example, laid bare the vulnerabilities of globally interconnected supply chains. Lockdowns, travel restrictions, and workforce disruptions rippled through supply networks, exposing weaknesses in contingency planning and risk mitigation. Businesses quickly learned that supply chain resilience is not merely a competitive advantage but a necessity in a rapidly changing world.

To thrive in this landscape of heightened complexity, organizations must adopt a proactive and holistic approach to supply chain management. This entails diversifying suppliers, implementing redundancy measures, and investing in real-time visibility and tracking technologies. It also involves conducting rigorous risk assessments to identify vulnerabilities and develop comprehensive contingency plans.

Globalization has unlocked immense potential for organizations to expand their reach and tap into diverse markets. Still, it has also amplified the importance of supply chain resilience. In navigating the complexities of today’s interconnected world, businesses that prioritize adaptability, agility, and proactive risk management will be better positioned to weather the storms and seize the opportunities that globalization offers.

Explore this link for a more extensive examination of the topic: Risk, resilience, and rebalancing in global value chains – McKinsey …

Many companies rely on a limited number of suppliers for critical components. A disruption in the supply chain of a key supplier can have cascading effects throughout the entire network.

The interconnected nature of modern supply chains underscores the critical importance of supply chain resilience. When companies heavily rely on a limited number of suppliers for essential components or materials, they expose themselves to vulnerabilities that can lead to extensive disruptions. To further explore this idea:

Supplier Concentration Risk: The practice of relying on a small number of suppliers, often referred to as supplier concentration, can leave companies susceptible to various risks. For instance, if a primary supplier encounters production issues, quality problems, or faces financial instability, it can disrupt the flow of critical inputs.

Cascading Effects: When a key supplier experiences a disruption, the impacts can cascade throughout the entire supply chain. Delays in component deliveries can lead to production slowdowns or stoppages, affecting product availability and customer orders. This, in turn, can result in financial losses and damage to a company’s reputation.

Diversification Strategies: To mitigate supply chain vulnerabilities, companies often employ diversification strategies. These strategies may involve sourcing critical components from multiple suppliers or even exploring alternative suppliers in different geographic regions. Diversification enhances supply chain flexibility and reduces reliance on a single source.

Supplier Relationship Management: Building strong relationships with suppliers is essential for supply chain resilience. Collaborative partnerships can facilitate open communication, early warning of potential issues, and joint problem-solving when disruptions occur. Companies that invest in supplier relationship management are better prepared to navigate supply chain challenges.

Risk Assessment: Conducting comprehensive risk assessments is crucial for identifying potential vulnerabilities in the supply chain. Companies can analyze various risk factors, such as geographic location, political stability, natural disasters, and economic conditions, to develop risk mitigation strategies.

Inventory Management: Maintaining strategic inventory levels can act as a buffer during supply chain disruptions. Safety stock, for example, can help bridge the gap during delays in component deliveries. However, managing excess inventory must be balanced with cost considerations.

Technology and Data Analytics: Leveraging technology and data analytics tools can enhance supply chain visibility and predictive capabilities. Real-time monitoring of supplier performance and demand patterns allows companies to respond proactively to potential disruptions.

Scenario Planning: Scenario planning involves developing contingency plans for various supply chain disruption scenarios. By considering a range of potential challenges and formulating response strategies in advance, companies can react more effectively when disruptions occur.

Resilience Testing: Some companies conduct supply chain resilience testing to assess their preparedness for disruptions. Simulating disruptions and evaluating the effectiveness of response plans can identify areas for improvement.

In summary, the reliance on a limited number of suppliers for critical components is a common practice in many industries. However, it comes with inherent risks that can result in supply chain disruptions. To mitigate these risks and enhance supply chain resilience, companies must adopt diversification strategies, strengthen supplier relationships, conduct thorough risk assessments, and leverage technology and data-driven insights to make informed decisions. These proactive measures can help companies navigate disruptions more effectively and maintain the continuity of their operations.

If you’d like to dive deeper into this subject, there’s more to discover on this page: CRR Supplemental Resource Guide, Volume 8: External …

Fluctuations in consumer demand, influenced by factors like seasonal trends or unexpected events (e.g., a pandemic), can strain supply chains that are not agile and responsive.

The dynamics of consumer demand are akin to a constantly shifting landscape, influenced by a multitude of factors. While it’s true that seasonal trends and unforeseen events like pandemics can exert significant pressure on supply chains that lack agility and responsiveness, it’s essential to delve deeper into how this phenomenon unfolds:

Seasonal Variability: The ebb and flow of consumer demand with the seasons is a well-documented aspect of the supply chain. For example, the holiday season prompts increased demand for gift items and festive foods. To navigate this, agile supply chains anticipate these fluctuations and adjust production and distribution accordingly. They understand that adaptability is the key to meeting the surges in demand and avoiding overstock during off-peak periods.

Global Events and Crises: Unexpected events, such as a pandemic or a natural disaster, can send shockwaves through the supply chain. For instance, the COVID-19 pandemic disrupted supply chains worldwide, leading to shortages of essential goods and reshaping consumer preferences. Agile supply chains not only pivot swiftly to address immediate challenges but also build resilience to withstand future shocks. They incorporate risk management strategies and diversify sourcing to reduce vulnerability.

Consumer Behavior and Preferences: Consumer behavior is a dynamic force. It’s influenced by factors like evolving tastes, health consciousness, ethical considerations, and emerging trends. Agile supply chains continuously gather data and consumer insights to stay attuned to shifting preferences. They can quickly adjust product portfolios, sourcing strategies, and marketing efforts to align with changing consumer sentiments.

Technology and Data-Driven Decision-Making: Technology plays a pivotal role in enhancing supply chain agility. Data analytics, artificial intelligence, and real-time monitoring enable supply chain managers to make informed decisions. They can predict demand patterns, optimize inventory, and streamline logistics, ensuring that products are available when and where consumers want them.

Collaborative Supply Chain Partnerships: Agile supply chains foster strong partnerships with suppliers, distributors, and retailers. Collaboration and open communication help identify potential bottlenecks and address them proactively. These partnerships extend beyond immediate stakeholders to include a network of trusted suppliers and logistics providers.

Lean Inventory Management: Maintaining excessively large inventories can be costly and inefficient. Agile supply chains adopt lean inventory practices, minimizing excess stock while ensuring that there’s always a buffer to meet sudden demand spikes. This lean approach optimizes resource utilization and reduces waste.

Adaptive Manufacturing: Agile supply chains often incorporate adaptive manufacturing techniques like just-in-time (JIT) production. This approach enables them to respond swiftly to changes in demand by producing goods in response to actual orders, reducing the risk of overproduction.

Sustainability and Resilience: Sustainability and resilience are intertwined with supply chain agility. Forward-thinking supply chains embrace sustainability practices not only for ethical reasons but also for long-term viability. Sustainable sourcing, reduced waste, and energy efficiency contribute to resilience by mitigating risks associated with resource scarcity and environmental impact.

In summary, the ability to adapt to fluctuations in consumer demand is a hallmark of an agile and responsive supply chain. It’s not merely about reacting to change but also about proactively anticipating and preparing for it. By leveraging technology, data-driven insights, collaborative partnerships, and sustainable practices, agile supply chains are better equipped to navigate the complexities of the modern marketplace and meet the ever-evolving needs of consumers.

Explore this link for a more extensive examination of the topic: The effect of lead-time on supply chain resilience performance …

In an increasingly digital world, cybersecurity breaches can disrupt operations, compromise sensitive data, and even halt production processes.

In our rapidly advancing digital era, the specter of cybersecurity breaches looms large, representing a formidable threat to organizations across industries. These breaches have the potential to wreak havoc on operations, compromise highly sensitive data, and even bring production processes to a screeching halt. Let’s delve deeper into the profound implications of cybersecurity breaches in the digital age:

Operational Disruption: Cyberattacks can lead to significant operational disruptions. For instance, a ransomware attack on a critical infrastructure facility can paralyze vital services, such as power grids or water treatment plants, affecting the lives of thousands. In the business world, a successful breach can disrupt supply chains, erode customer trust, and result in substantial financial losses.

Data Compromise: Cybersecurity breaches can expose a treasure trove of sensitive data, ranging from personal information to proprietary business secrets. The unauthorized access and theft of this data can have far-reaching consequences, including identity theft, financial fraud, and reputational damage.

Production Halts: In industrial sectors, particularly those embracing automation and Industry 4.0 principles, cyberattacks pose a unique threat. Intrusions into critical control systems can halt production processes, causing significant financial losses and potential safety hazards. For example, an attack on a pharmaceutical manufacturer’s automated production line could result in drug shortages.

Financial Ramifications: Recovering from a cybersecurity breach can be a costly endeavor. Organizations often incur expenses related to investigating the breach, restoring systems, and implementing enhanced security measures. Additionally, they may face legal liabilities and fines if customer or employee data is compromised.

Reputation Damage: Perhaps one of the most intangible yet profound impacts of cyberattacks is the damage they inflict on an organization’s reputation. Customers and stakeholders may lose trust in a company that fails to safeguard their data or experiences frequent disruptions due to security breaches. Rebuilding trust can be a long and arduous process.

Intellectual Property Theft: Businesses invest heavily in research and development to gain a competitive edge. Cyberattacks that result in the theft of intellectual property can undermine these efforts, eroding a company’s competitive advantage and potentially benefiting rival organizations.

National Security Concerns: Beyond the corporate world, cybersecurity breaches can have national security implications. State-sponsored cyberattacks or breaches targeting critical infrastructure can compromise a nation’s ability to defend itself or respond to emergencies.

Loss of Confidence: Cybersecurity breaches can also erode public confidence in digital systems and technology, deterring individuals and organizations from embracing the full potential of the digital age. This loss of confidence can stifle innovation and economic growth.

To combat these challenges, organizations and governments must prioritize cybersecurity. This includes investing in robust cybersecurity measures, fostering a culture of security awareness, and collaborating on a global scale to thwart cyber threats. As our world becomes increasingly interconnected and reliant on digital technology, safeguarding against cybersecurity breaches is not just a matter of choice; it is a fundamental necessity to ensure the security, stability, and progress of our digital age.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Cybersecurity Supply Chain Risk Management | CSRC

Effective risk management is fundamental to supply chain resilience. It involves a systematic approach to identifying, assessing, and mitigating risks, as well as developing contingency plans for when disruptions occur. Here are key strategies:

Diversification of Suppliers: Relying on a single supplier can be risky. Companies should diversify their supplier base to reduce vulnerability to disruptions.

Data Analytics: Advanced analytics and data-driven insights help in predicting and mitigating supply chain risks. Machine learning and AI can analyze vast amounts of data to identify potential issues before they escalate.

Inventory Management: Maintaining optimal inventory levels is crucial. Too much inventory ties up capital, while too little can lead to stockouts. Employing demand forecasting tools can help strike the right balance.

Communication and Collaboration: Establishing strong communication channels with suppliers, partners, and customers is vital. Collaborative relationships can facilitate quicker responses to disruptions.

Cybersecurity Measures: With the increasing digitalization of supply chains, protecting against cyber threats is paramount. Robust cybersecurity measures can safeguard critical data and operations.

Scenario Planning: Supply chain professionals should conduct scenario planning exercises to prepare for various disruptions, from natural disasters to geopolitical issues.

Continuous Monitoring: Regularly monitoring the entire supply chain allows for early detection of potential risks. Real-time tracking and monitoring systems are valuable tools.

Redundancy and Backup Plans: Identifying critical components and having redundancy or backup plans for these components can ensure smoother operations during disruptions.

By implementing these strategies, businesses can enhance their supply chain resilience and effectively manage risks, safeguarding their operations in an increasingly complex and interconnected world.

For a comprehensive look at this subject, we invite you to read more on this dedicated page: Can supply chain risk management practices mitigate the disruption …

Reduce dependency on a single supplier by diversifying sources, which can enhance resilience and provide alternatives during disruptions.

Diversifying sources is a strategic approach that offers numerous benefits beyond merely reducing dependency on a single supplier. This practice, whether applied in supply chains, energy procurement, or investment portfolios, can enhance resilience and provide valuable alternatives during disruptions or periods of uncertainty. Here’s an extended exploration of the advantages of diversification:

Enhancing Resilience: Diversification is like spreading your risk across multiple assets or sources. In the context of supply chains, having multiple suppliers or sources for critical materials or components means that a disruption in one area is less likely to halt production or operations entirely. This resilience is particularly crucial in industries where downtime can lead to significant losses.

Mitigating Supply Chain Risks: Supply chains are susceptible to various risks, including geopolitical tensions, natural disasters, economic fluctuations, and labor strikes. Diversification minimizes the impact of these risks by ensuring that you have backup options when one part of the supply chain is affected.

Ensuring Continuity of Operations: When you rely on a single supplier or source, you are vulnerable to their specific challenges or limitations. For instance, if a primary supplier encounters financial trouble, quality issues, or logistical problems, your operations could suffer. Diversification safeguards against such scenarios.

Managing Cost Fluctuations: Commodities and raw materials often experience price volatility. Diversifying sources allows you to capitalize on favorable pricing from different suppliers and mitigate the impact of price spikes or shortages from a single source.

Driving Innovation: Engaging with multiple suppliers can foster competition and innovation within your supply chain. Suppliers may vie for your business by offering improved quality, lower prices, or new technology solutions, ultimately benefiting your organization.

Adapting to Market Changes: Markets evolve, and consumer preferences can shift. Diversifying your product offerings or sourcing options enables you to adapt more quickly to changing market dynamics, positioning your organization for continued success.

Optimizing Resource Allocation: Diversification enables you to allocate resources strategically. You can direct investments and efforts to areas where they are most needed or have the greatest potential for growth, rather than being tied to a single supplier’s fortunes.

Strengthening Negotiating Power: When you have multiple sourcing options, you are in a better position to negotiate favorable terms with suppliers. Competition among suppliers for your business can lead to better pricing, terms, and conditions.

Global Supply Chain Resilience: In a globalized world, supply chains often span multiple countries and continents. Diversification can extend to international suppliers, helping to ensure resilience against international trade disruptions, tariffs, or geopolitical tensions.

Meeting Ethical and Sustainability Goals: Diversifying suppliers may allow you to work with partners who align more closely with your organization’s ethical, environmental, or sustainability values, helping you achieve corporate responsibility objectives.

In essence, diversification is a cornerstone of risk management and business resilience. It offers a proactive strategy for navigating uncertainty and disruptions while providing the flexibility and adaptability needed to thrive in an ever-changing global landscape. Whether applied to sourcing, investments, or other aspects of business, diversification is a powerful tool for building resilience and ensuring long-term success.

To expand your knowledge on this subject, make sure to read on at this location: The effects of supply chain diversification during the COVID-19 crisis …

Create a comprehensive map of your supply chain, including identifying critical nodes and dependencies. This helps in understanding vulnerabilities and developing targeted risk management plans.

Creating a comprehensive map of your supply chain is akin to charting a course through uncharted waters. It involves meticulously plotting the intricate web of suppliers, manufacturers, distributors, and logistics providers that constitute the backbone of your operations. But beyond the complexity, this visual representation serves as a powerful tool for understanding vulnerabilities and developing targeted risk management plans.

Node Identification: At the heart of supply chain mapping is the identification of critical nodes. These are the pivotal points within your supply chain where the flow of goods and services converges and, consequently, where disruptions can have the most significant impact. Identifying these nodes can include pinpointing key suppliers, manufacturing facilities, distribution centers, and transportation hubs. By recognizing these critical junctures, you gain clarity on where to focus your risk management efforts.

Dependency Analysis: The next step is to analyze dependencies. This involves assessing the interconnections between various nodes in your supply chain. For example, understanding which suppliers provide critical components for your manufacturing process or which transportation routes are vital for timely delivery. By comprehending these dependencies, you can gauge the ripple effects of a disruption at one node on the entire supply chain.

Risk Assessment: With critical nodes and dependencies identified, you can conduct a comprehensive risk assessment. This entails evaluating the specific risks associated with each node and dependency. For instance, a supplier located in an earthquake-prone region may pose a natural disaster risk, while a geopolitical hotspot where your manufacturing plant is located may present political instability risks. By quantifying these risks, you can prioritize them based on their potential impact and likelihood.

Contingency Planning: Armed with a clear understanding of vulnerabilities and risks, you can then develop targeted risk management plans. These plans should outline the steps to be taken in response to disruptions at critical nodes. For example, you may develop alternative sourcing strategies or establish redundant distribution centers. Contingency plans should also detail communication strategies, responsibilities, and timelines to ensure a coordinated response.

Monitoring and Adaptation: Supply chain mapping is not a static exercise; it’s an ongoing process. Regularly updating your map and reassessing risks is vital. As your supply chain evolves and external factors change, new vulnerabilities and dependencies may emerge. By continuously monitoring and adapting, you can ensure that your risk management plans remain effective and relevant.

Transparency and Collaboration: Supply chain mapping also promotes transparency and collaboration within your organization and with external partners. Sharing the map and risk assessments with key stakeholders fosters a shared understanding of vulnerabilities and risk mitigation strategies. It can also enable more effective collaboration with suppliers, enabling them to adopt risk management practices that align with your goals.

In conclusion, creating a comprehensive supply chain map is not merely an exercise in visualization; it’s a strategic imperative. It empowers organizations to proactively identify vulnerabilities, assess risks, and develop targeted risk management plans. In a world where disruptions are inevitable, this level of preparedness can mean the difference between a resilient supply chain that weathers the storm and one that crumbles under pressure.

To delve further into this matter, we encourage you to check out the additional resources provided here: Supply Chain Resilience Guide | FEMA

Regularly assess potential risks and their impact on the supply chain. Consider both internal and external factors, such as geopolitical events, natural disasters, and economic trends.

Regularly assessing potential risks and their impact on the supply chain is a proactive approach that forms the foundation of effective risk management. This ongoing process involves a comprehensive evaluation of a wide range of internal and external factors that can influence supply chain operations. Here are key elements to consider when conducting risk assessments:

Geopolitical Events: Geopolitical factors can have a significant impact on the supply chain. Changes in trade policies, tariffs, sanctions, and political instability in key regions can disrupt the movement of goods, alter sourcing strategies, and affect market access. Staying informed about global political developments and their potential repercussions is essential.

Natural Disasters: Natural disasters, such as earthquakes, hurricanes, floods, and wildfires, can disrupt transportation, damage infrastructure, and interrupt the flow of goods. Assessing the vulnerability of supply chain locations to specific types of natural disasters and developing mitigation strategies, such as diversifying sourcing or implementing disaster recovery plans, is crucial.

Economic Trends: Economic factors, including inflation, currency fluctuations, and economic downturns, can impact supply chain costs and demand patterns. Monitoring economic trends and their potential consequences on production costs, pricing strategies, and consumer behavior helps organizations make informed decisions.

Supplier Risks: Evaluating the stability and resilience of suppliers is fundamental to risk assessment. Factors such as financial health, capacity, location, and dependence on single sources or regions can influence a supplier’s ability to meet demand consistently. Developing alternative sourcing options and supplier relationships can mitigate these risks.

Regulatory Changes: Changes in regulations related to product safety, environmental standards, or customs procedures can affect supply chain compliance and operational efficiency. Keeping abreast of evolving regulatory landscapes and adapting supply chain processes to ensure compliance is essential.

Market Trends: Consumer preferences, market dynamics, and emerging trends can impact demand forecasts and product lifecycles. Regularly monitoring market trends and consumer behavior allows organizations to adjust production plans, inventory levels, and distribution strategies accordingly.

Technological Advancements: Technology is a double-edged sword; it can both enhance and disrupt supply chains. Evaluating emerging technologies, such as automation, blockchain, and data analytics, and their potential to optimize supply chain operations or create vulnerabilities is essential for staying competitive.

Cybersecurity Threats: As supply chains become more digitally interconnected, the risk of cybersecurity threats increases. Assessing vulnerabilities in digital infrastructure and implementing robust cybersecurity measures, including data encryption, access controls, and employee training, is crucial.

Environmental Sustainability: Environmental risks, such as climate change, resource scarcity, and environmental regulations, can affect the availability of raw materials, transportation costs, and consumer preferences. Incorporating sustainability practices into the supply chain strategy can mitigate these risks.

Pandemic Preparedness: The COVID-19 pandemic underscored the importance of pandemic preparedness in risk assessment. Organizations should evaluate their ability to maintain operations during a health crisis, considering factors like remote work capabilities, supply chain disruptions, and employee safety.

Third-Party Risks: Beyond suppliers, third-party logistics providers, transportation partners, and subcontractors can introduce additional risks. Assessing the capabilities and resilience of these external partners and ensuring they align with supply chain goals is essential.

Scenario Planning: Conducting scenario-based risk assessments can help organizations anticipate and prepare for specific disruption scenarios. By simulating disruptions and evaluating potential responses, organizations can develop robust contingency plans.

Incorporating these elements into regular risk assessments enables organizations to proactively identify vulnerabilities, develop mitigation strategies, and enhance overall supply chain resilience. By staying vigilant and adaptable, businesses can navigate the complex and dynamic landscape of global supply chain risks effectively.

For a comprehensive look at this subject, we invite you to read more on this dedicated page: Cybersecurity Supply Chain Risk Management | CSRC

Develop contingency plans for various risk scenarios, ensuring that employees are aware of these plans and can execute them effectively when needed.

Developing comprehensive contingency plans for various risk scenarios is a fundamental aspect of modern business resilience. These plans serve as a roadmap for organizations to navigate through unexpected disruptions, minimizing the impact on operations and ensuring business continuity. However, the effectiveness of these plans hinges not only on their formulation but also on the awareness and readiness of employees to execute them when the need arises.

Risk Assessment: The first step in creating robust contingency plans is a thorough risk assessment. Organizations must identify potential threats and vulnerabilities that could disrupt their operations. These threats can encompass a wide range of scenarios, including natural disasters, supply chain disruptions, cybersecurity breaches, and public health crises like pandemics.

Plan Formulation: Once potential risks are identified, organizations can formulate contingency plans tailored to each specific scenario. These plans should outline clear steps and procedures to be followed when a crisis occurs. They should also designate responsibilities and chain of command, ensuring that decision-makers and responders are well-defined.

Employee Training: Creating awareness among employees is essential. Regular training and drills can help familiarize the workforce with the contingency plans and equip them with the necessary skills to execute them effectively. This not only boosts confidence but also minimizes the risk of panic or confusion during an actual crisis.

Communication Protocols: Effective communication is often the linchpin of crisis management. Organizations should establish communication protocols that ensure timely and accurate information flows both internally and externally. This includes channels for notifying employees, customers, suppliers, and other stakeholders about the situation and the steps being taken.

Testing and Simulation: Contingency plans should be tested through simulation exercises and drills. These tests help identify any gaps or weaknesses in the plans and provide an opportunity to fine-tune them for better performance. Regular testing also keeps employees prepared and ensures that plans remain up-to-date.

Resource Allocation: Adequate resources, both human and material, must be allocated to support the execution of contingency plans. This includes having access to necessary tools, technologies, and emergency supplies. It also involves having trained personnel on standby or readily available.

Feedback and Improvement: Contingency plans should not be static documents. They should evolve and improve based on lessons learned from real incidents and simulations. Gathering feedback from employees and stakeholders who were part of crisis response efforts is crucial for refining the plans over time.

Documentation and Documentation: Thorough documentation of contingency plans and related procedures is essential. This documentation should be easily accessible and regularly reviewed and updated to reflect changes in the organization’s structure, operations, or external factors.

Legal and Regulatory Compliance: Depending on the industry and location, organizations may be subject to specific legal and regulatory requirements regarding contingency planning and crisis management. Ensuring compliance with these standards is imperative.

In today’s dynamic and interconnected business environment, the ability to respond effectively to unexpected disruptions is a key differentiator. Contingency planning, when coupled with employee awareness and readiness, forms a powerful shield against the uncertainties of the modern world. It not only safeguards business operations but also enhances an organization’s reputation for resilience and dependability.

For additional details, consider exploring the related content available here What is a resilient supply chain? | agility and risk management | SAP

Leverage technology and data analytics to monitor and predict potential disruptions. Advanced analytics can provide real-time insights into supply chain performance, enabling proactive risk management.

Leveraging technology and data analytics to monitor and predict potential disruptions in the supply chain is a crucial aspect of modern supply chain management. Here’s an extended exploration of this idea:

Real-Time Visibility: Technology, such as Internet of Things (IoT) devices, sensors, and RFID tags, provides real-time visibility into the movement of goods and the status of inventory at various points in the supply chain. This level of visibility enables companies to track the location and condition of products, monitor production processes, and anticipate potential delays or bottlenecks.

Predictive Analytics: Advanced data analytics, including machine learning and predictive modeling, can analyze historical data and current variables to forecast potential disruptions. For example, predictive algorithms can take into account factors such as weather patterns, geopolitical events, or supplier performance to anticipate disruptions before they occur. This allows companies to implement proactive risk mitigation strategies.

Inventory Optimization: Data analytics can help optimize inventory levels by analyzing demand patterns, supplier lead times, and historical sales data. By maintaining the right amount of inventory, companies can minimize excess stock and reduce the risk of shortages during disruptions.

Supplier Performance Monitoring: Technology-driven tools can continuously assess and monitor supplier performance. Key performance indicators (KPIs) can be tracked to evaluate factors such as on-time deliveries, quality control, and lead times. Any deviations from established KPIs can trigger alerts, enabling companies to address potential issues promptly.

Demand Forecasting: Accurate demand forecasting is critical for supply chain planning. Data analytics can analyze customer behavior, market trends, and historical sales data to generate more accurate demand forecasts. This helps companies align their production and inventory levels with actual customer demand, reducing the risk of overstock or understock situations.

Supply Chain Simulation: Some companies use supply chain simulation tools that allow them to model various scenarios and disruptions. By simulating disruptions, companies can test the effectiveness of different mitigation strategies and refine their response plans.

Collaborative Platforms: Technology-driven collaborative platforms enable real-time communication and data sharing among supply chain partners. This transparency facilitates coordinated responses to disruptions. For example, if a supplier experiences a delay, the affected parties can quickly adjust production schedules and logistics plans.

Blockchain Technology: Blockchain technology offers a secure and transparent way to trace the origins and movements of products in the supply chain. It can enhance transparency and traceability, making it easier to identify the source of disruptions and take appropriate corrective actions.

Scenario Planning: Using historical data and predictive analytics, companies can engage in scenario planning. By considering various disruption scenarios, companies can develop response plans in advance, streamlining their ability to react to unexpected events.

Continuous Improvement: Technology and data analytics allow for continuous improvement in supply chain processes. By analyzing performance metrics and identifying areas for enhancement, companies can iteratively refine their supply chain strategies to become more resilient over time.

In conclusion, technology and data analytics are powerful tools that enable companies to monitor supply chain performance in real-time, predict potential disruptions, and take proactive risk management measures. By leveraging these tools, companies can enhance supply chain resilience, reduce operational risks, and ensure the continuity of their operations even in the face of unexpected challenges.

For a comprehensive look at this subject, we invite you to read more on this dedicated page: Artificial intelligence and big data analytics for supply chain …

Collaborate with suppliers, partners, and industry peers to share information and best practices for risk mitigation.

Collaboration is a cornerstone of risk mitigation in today’s interconnected business landscape. When it comes to supply chain management, partnering with suppliers, industry peers, and stakeholders can yield invaluable benefits in navigating uncertainties and enhancing resilience. Here’s an extended look at the idea of collaboration for risk mitigation:

Supplier Collaboration: Building strong relationships with suppliers is fundamental to supply chain resilience. Collaborative efforts with suppliers go beyond mere transactions; they involve shared goals and risk management strategies. Key aspects of supplier collaboration include:

Transparent Communication: Open and transparent communication channels allow for timely updates on supply chain disruptions, quality issues, or changes in demand.

Joint Risk Assessment: Collaborative risk assessments help identify potential vulnerabilities in the supply chain. Both parties can work together to develop mitigation plans.

Shared Data and Insights: Sharing data and market insights can provide a more comprehensive view of demand forecasts and supply chain dynamics. This shared information enables better decision-making.

Contingency Planning: Collaborative contingency planning involves joint efforts to create alternative sourcing strategies, backup suppliers, and disaster recovery plans.

Industry Peer Networks: Being part of industry associations and peer networks provides access to a wealth of knowledge and best practices. Industry peers often face similar challenges and can offer insights on how to navigate them. Key aspects of industry peer collaboration include:

Benchmarking: Comparing performance metrics and best practices with peers helps identify areas for improvement and innovation within the supply chain.

Knowledge Sharing: Industry peer networks often organize conferences, webinars, and forums where members can share experiences, strategies, and lessons learned from risk mitigation efforts.

Collective Action: In some cases, industry peers may collaborate on initiatives that benefit the entire sector, such as joint research on emerging risks or lobbying for regulatory changes that enhance industry resilience.

Cross-Functional Collaboration: Collaboration should extend beyond supply chain and procurement teams. Involving cross-functional teams, including finance, legal, and IT, is essential for comprehensive risk management. Key aspects of cross-functional collaboration include:

Risk Assessment: Collaborating with legal and compliance teams to conduct thorough risk assessments helps identify legal and regulatory risks that may impact the supply chain.

Financial Planning: Finance teams play a crucial role in assessing the financial impact of supply chain disruptions and ensuring adequate financial reserves for risk mitigation.

Technology Integration: IT teams can support supply chain resilience by implementing technology solutions for data analytics, monitoring, and automation, enabling rapid response to disruptions.

Supply Chain Ecosystem Collaboration: Recognizing that supply chains are part of broader ecosystems, collaborating with customers and other stakeholders can enhance resilience. Key aspects of ecosystem collaboration include:

Customer Feedback: Actively seeking feedback from customers can help identify evolving demands, preferences, and potential disruptions that may impact the supply chain.

Sustainability Initiatives: Collaborating with stakeholders on sustainability efforts can lead to more responsible sourcing practices and reduce environmental risks.

Regulatory Compliance: Engaging with regulatory authorities and compliance bodies to stay informed about changes in regulations and standards is vital for risk mitigation.

In conclusion, collaboration is a multifaceted approach to risk mitigation in supply chain management. It involves sharing information, best practices, and insights with suppliers, industry peers, cross-functional teams, and stakeholders. By fostering a culture of collaboration, organizations can proactively identify and address risks, enhance supply chain resilience, and adapt to the ever-changing business landscape.

You can also read more about this here: Supply Chain Resilience: Unleashing the Power of Collaboration in …

Investing in supply chain resilience and risk management offers several advantages:

Investing in supply chain resilience and risk management is akin to fortifying the foundation of a house to withstand unforeseen storms. It is a strategic imperative that offers a multitude of advantages, ensuring that organizations can navigate the turbulent waters of today’s global business landscape with confidence and adaptability. Here, we explore the multifaceted benefits of such investments:

Business Continuity: Perhaps the most immediate advantage is the preservation of business continuity. When disruptions occur, whether due to natural disasters, geopolitical tensions, or unforeseen supply chain hiccups, a resilient supply chain ensures that operations can continue, minimizing downtime and revenue loss.

Risk Mitigation: Effective risk management allows organizations to identify, assess, and mitigate potential threats to the supply chain. By proactively addressing vulnerabilities, businesses can reduce the impact of disruptions and avoid costly consequences.

Cost Reduction: Resilience measures often involve streamlining supply chain processes, reducing waste, and optimizing inventory management. These efficiencies can lead to cost reductions, improving the organization’s overall financial health.

Competitive Advantage: Organizations with resilient supply chains are better positioned to weather disruptions and adapt to changing market conditions. This adaptability can translate into a competitive advantage, allowing them to capture market share from less-prepared competitors.

Supplier Relationships: Investing in supply chain resilience also fosters stronger relationships with suppliers. Collaborative efforts to improve resilience can lead to more transparent, efficient, and mutually beneficial partnerships.

Reputation Protection: A resilient supply chain safeguards an organization’s reputation. When disruptions occur, customers and stakeholders appreciate a company that can maintain consistent service and product availability, enhancing trust and loyalty.

Regulatory Compliance: Many industries face regulatory requirements related to supply chain risk management and reporting. Meeting these obligations not only avoids legal repercussions but also demonstrates a commitment to responsible business practices.

Innovation: Resilience initiatives often drive innovation within an organization. The search for more robust and adaptable supply chain solutions can lead to the development of new technologies, processes, and business models.

Sustainability: A resilient supply chain can also be a sustainable one. By optimizing logistics and reducing waste, organizations can minimize their environmental footprint, aligning with growing consumer and regulatory demands for eco-conscious practices.

Long-Term Viability: In a world characterized by increasing complexity and uncertainty, investing in supply chain resilience is an investment in an organization’s long-term viability. It positions the company to not only survive but thrive in an ever-changing business landscape.

Supply Chain Transparency: Resilience efforts often necessitate greater transparency throughout the supply chain. This transparency not only helps in risk identification but also aligns with consumer demands for more information about product origins and ethical practices.

Customer Satisfaction: Ultimately, a resilient supply chain contributes to customer satisfaction. Customers value consistency, reliability, and responsiveness. When an organization can deliver on these fronts, it fosters loyalty and repeat business.

In conclusion, investing in supply chain resilience and risk management is a strategic imperative that offers a multitude of advantages. It is an acknowledgment that in today’s interconnected and unpredictable world, proactive measures are necessary to safeguard business continuity, enhance competitiveness, and protect reputation. By prioritizing resilience, organizations can not only survive disruptions but also thrive in the face of adversity, ensuring their long-term success and sustainability.

Additionally, you can find further information on this topic by visiting this page: Is your supply chain risk blind—or risk resilient? | McKinsey

Minimize disruptions and maintain operations, ensuring that customers receive products and services as planned.

Supply chain resilience is not solely about reacting to disruptions; it also involves proactive measures to minimize their impact and maintain smooth operations. Here are some strategies to achieve this:

Supplier Risk Assessment: Regularly assess the risk profile of your suppliers. Identify potential vulnerabilities and work with suppliers to develop risk mitigation plans. This proactive approach can help prevent disruptions before they occur.

Supplier Audits and Certifications: Conduct supplier audits to ensure they adhere to quality and safety standards. Certifications like ISO standards can provide assurance of supplier reliability. These measures help in reducing the likelihood of supply interruptions due to quality issues.

Supplier Collaboration: Establish strong relationships with key suppliers. Collaborative partnerships can lead to better communication, shared risk management, and coordinated responses to disruptions. Work together to identify and address vulnerabilities in the supply chain.

Supply Chain Mapping: Create a detailed map of your supply chain, including all suppliers, sub-suppliers, and dependencies. Understanding the intricacies of your supply network enables you to anticipate potential weak points and devise contingency plans.

Inventory Optimization: While carrying excess inventory is costly, maintaining buffer stock for critical components can provide a safety net during disruptions. Employ advanced inventory optimization techniques to strike the right balance between cost and resilience.

Transportation and Logistics Redundancy: Diversify your transportation and logistics options. Have multiple shipping routes, carriers, and distribution centers at your disposal. This redundancy can help reroute shipments during disruptions.

Scenario Planning: Regularly engage in scenario planning exercises. Simulate various disruption scenarios and develop response plans for each. This proactive approach ensures that your organization is well-prepared for unexpected events.

Technology Integration: Invest in supply chain technology that provides real-time visibility into your operations. Advanced analytics, IoT sensors, and AI-driven insights can help you detect issues early and respond swiftly.

Cross-Functional Collaboration: Encourage cross-functional collaboration within your organization. Involving teams from procurement, operations, logistics, and risk management in supply chain resilience efforts ensures a holistic approach.

Continuous Improvement: Establish a culture of continuous improvement in your supply chain management. Regularly review and update your resilience strategies based on lessons learned from past disruptions and changing market conditions.

By adopting these proactive measures, organizations can enhance their supply chain resilience, reduce the likelihood of disruptions, and ensure uninterrupted operations, ultimately delivering better service to customers.

Explore this link for a more extensive examination of the topic: Is your supply chain risk blind—or risk resilient? | McKinsey

Proactive risk management can reduce the financial impact of disruptions, including lower costs associated with recovery efforts.

Proactive risk management is not merely a prudent measure; it is a strategic imperative for organizations aiming to safeguard their financial stability and minimize the financial impact of disruptions. While the benefits of proactive risk management extend far beyond cost reduction, it’s worth exploring how such measures can lead to lower costs associated with recovery efforts and other financial implications:

Early Detection and Prevention: Proactive risk management involves identifying potential risks and vulnerabilities before they escalate into full-blown crises. By addressing these issues at an early stage, organizations can prevent disruptions or mitigate their severity, saving considerable financial resources that would otherwise be needed for recovery.

Reduced Downtime: Disruptions often lead to downtime, which can result in substantial revenue losses. Proactive risk management strategies, such as redundant systems, disaster recovery plans, and business continuity measures, can significantly reduce downtime, enabling organizations to maintain operations and minimize financial setbacks.

Insurance Premiums: Organizations that demonstrate a commitment to risk management and have effective strategies in place are often rewarded with lower insurance premiums. Insurance providers view proactive risk mitigation as a sign of reduced risk exposure, leading to cost savings for the organization.

Legal and Regulatory Compliance: Non-compliance with laws and regulations can lead to hefty fines and legal expenses. Proactive risk management ensures that an organization remains compliant, avoiding costly legal battles and penalties that can drain financial resources.

Brand Protection: Disruptions, especially those related to crises or scandals, can tarnish a company’s reputation. The financial impact of brand damage can be extensive, leading to lost customers, decreased sales, and increased marketing and PR expenses. Proactive risk management, including reputation management strategies, helps protect the brand and avoid these costly repercussions.

Supply Chain Efficiency: Organizations reliant on intricate supply chains can experience significant financial losses during supply chain disruptions. Proactive measures, such as supply chain mapping, diversification of suppliers, and demand forecasting, enhance supply chain resilience and minimize disruptions’ financial toll.

Employee Productivity: Disruptions can disrupt employee productivity, leading to lost work hours and decreased output. Proactive risk management involves employee training, wellness programs, and measures to ensure a safe and productive work environment, reducing the financial impact of disruptions on human resources.

Customer Retention: Maintaining customer trust and loyalty is essential for long-term financial health. Proactive risk management can include customer communication plans and strategies for addressing customer concerns during disruptions, thereby retaining customer goodwill and revenue.

Financial Preparedness: Proactive risk management also involves financial planning for potential disruptions. Establishing contingency funds or access to lines of credit can provide financial resources when needed, reducing the financial strain of recovery efforts.

Strategic Investments: Organizations that proactively identify and manage risks may strategically invest in technologies, processes, and infrastructure that enhance resilience. While these investments have upfront costs, they can yield substantial long-term savings by minimizing the financial impact of disruptions.

In summary, proactive risk management represents a comprehensive approach to safeguarding an organization’s financial health. While it encompasses various strategies to prevent or mitigate disruptions, its financial benefits are substantial. Lower recovery costs, reduced downtime, and enhanced risk mitigation strategies all contribute to a stronger financial position for organizations in an ever-changing and unpredictable business landscape.

If you’d like to dive deeper into this subject, there’s more to discover on this page: BUILDING RESILIENT SUPPLY CHAINS, REVITALIZING …

Organizations with resilient supply chains are better equipped to adapt to changing market conditions and outperform competitors.

In the fast-paced and ever-changing landscape of today’s global markets, the adaptability and resilience of a supply chain can make all the difference between an organization’s success and its struggles. Let’s delve deeper into how organizations with resilient supply chains gain a significant edge over their competitors:

Flexibility in Response to Market Shifts: Resilient supply chains are designed to respond swiftly to market shifts. When consumer preferences change, or unforeseen disruptions occur, these organizations can quickly adjust their sourcing, production, and distribution strategies. For example, a clothing retailer with a resilient supply chain can swiftly shift production from summer wear to winter apparel in response to unexpected weather changes. This adaptability ensures that they remain competitive and can meet customer demand even in turbulent times.

Minimized Downtime: Disruptions are inevitable, but their impact can vary greatly depending on an organization’s supply chain resilience. Companies with resilient supply chains are better prepared to minimize downtime during disruptions. They have contingency plans in place to reroute shipments, find alternative suppliers, or temporarily adjust their production processes. This means less revenue loss and quicker recovery compared to competitors who may face prolonged interruptions.

Improved Customer Satisfaction: In an age where customer expectations are soaring, organizations that consistently deliver on their promises gain a competitive edge. Resilient supply chains contribute to this by ensuring a reliable supply of products. Customers can trust that their orders will be fulfilled on time, leading to higher levels of satisfaction and loyalty. This not only retains existing customers but also attracts new ones through positive word-of-mouth.

Cost Efficiency: Resilient supply chains are not just about reacting to disruptions; they’re also about preventing them. By conducting thorough risk assessments and diversifying suppliers and sourcing regions, organizations can proactively reduce the likelihood of disruptions. This means fewer emergency expenses, such as rush shipments or last-minute sourcing, resulting in cost savings that can be reinvested or passed on to customers, making their products more competitively priced.

Competitive Advantage: Supply chain resilience can be a significant differentiator in competitive markets. Organizations that can consistently deliver products in a timely and reliable manner can gain a reputation for dependability. This reputation can translate into a competitive advantage, helping them secure contracts, partnerships, and market share that might have otherwise gone to less resilient competitors.

Long-Term Sustainability: Resilient supply chains are not just focused on short-term gains. They also consider long-term sustainability. By sourcing materials responsibly, reducing waste, and adopting sustainable practices, organizations can align themselves with growing consumer demand for eco-friendly products. This positions them well for the future as sustainability becomes an increasingly significant factor in purchasing decisions.

In essence, organizations with resilient supply chains are better equipped to navigate the complex and unpredictable terrain of the modern business world. They can adapt to market changes, weather disruptions, and consistently meet customer demands. As a result, they not only survive in competitive markets but often thrive, outperforming competitors and securing their position as industry leaders.

For additional details, consider exploring the related content available here Make Supply Chain Resilience a Competitive Advantage

Consistency in delivering products and services, even during disruptions, builds trust and loyalty among customers.

Consistency in delivering products and services, even in the face of disruptions, is a cornerstone of building and maintaining trust and loyalty among customers. This principle holds true in various industries and has several significant implications:

Reliability: Customers value reliability in the products and services they depend on. Consistently meeting delivery schedules, quality standards, and service expectations demonstrates an organization’s commitment to reliability. It assures customers that they can rely on your brand, even when challenges arise.

Brand Reputation: Building a strong brand reputation requires consistency. When customers consistently receive high-quality products or services, they associate your brand with reliability and excellence. Positive experiences lead to word-of-mouth recommendations and brand advocacy, which can drive customer loyalty.

Customer Confidence: Consistency fosters customer confidence. During disruptions or uncertainties, customers are more likely to remain loyal to brands they trust. Knowing that your organization will continue to deliver despite challenges provides customers with peace of mind.

Customer Loyalty: Consistency is a key driver of customer loyalty. Customers who experience consistent and positive interactions with your brand are more likely to become repeat buyers. They are also less likely to explore alternatives or switch to competitors, even when faced with tempting offers.

Emotional Connection: Consistency helps build emotional connections with customers. When customers know what to expect from your brand, they develop a sense of familiarity and trust. Emotional bonds with a brand can lead to long-term loyalty and customer advocacy.

Resilience in Disruptions: During disruptions, maintaining consistency can be challenging but is essential. Organizations that can adapt and continue delivering products and services, even with modifications, are better positioned to weather crises. This adaptability demonstrates resilience and reinforces trust.

Competitive Advantage: Consistency can be a significant competitive advantage. In industries where customer trust is paramount, such as healthcare, finance, and food services, consistent performance sets you apart from competitors. It becomes a compelling reason for customers to choose your brand.

Reduced Customer Churn: When customers consistently receive what they expect, they are less likely to churn or switch to competitors. Reducing customer churn is not only cost-effective but also contributes to long-term profitability.

Positive Customer Experiences: Positive customer experiences result from consistent service delivery. These experiences lead to higher customer satisfaction, which, in turn, influences customer retention and loyalty.

Value Proposition: Consistency is a fundamental part of your value proposition. It’s the promise you make to customers about the quality and reliability of your offerings. Fulfilling this promise strengthens your value proposition and differentiates you from competitors.

In summary, consistency is a powerful driver of customer trust, loyalty, and brand equity. Organizations that prioritize delivering consistent products and services, even in challenging circumstances, are more likely to foster enduring customer relationships and maintain a competitive edge. Building a reputation for reliability is an investment that pays dividends in customer loyalty and business success.

Don’t stop here; you can continue your exploration by following this link for more details: Trust in supply chains | Deloitte Insights

Compliance with regulations and industry standards related to risk management and supply chain resilience is critical in many sectors.

Compliance with regulations and industry standards related to risk management and supply chain resilience is not just a box to check; it’s a fundamental imperative across various sectors. These guidelines and mandates serve as essential guardrails for organizations, ensuring that they prioritize safety, reliability, and adaptability in the face of disruptions. Here’s why compliance in these areas is critical:

Legal Obligations: In many jurisdictions, there are legal requirements and regulations that organizations must adhere to in terms of risk management and supply chain resilience. Failure to comply can result in legal consequences, fines, or even business closures. Compliance is not merely a recommendation but a legal obligation.

Consumer Trust: Today’s consumers are more informed and conscientious than ever. They expect the products they purchase to be safe, reliable, and sourced responsibly. Compliance with industry standards and regulations is a means of demonstrating commitment to these principles, earning consumer trust, and safeguarding an organization’s reputation.

Risk Mitigation: Regulations and industry standards are often developed based on best practices and lessons learned from past incidents. Complying with these guidelines is a practical way to mitigate risks and avoid costly disruptions. It’s essentially learning from the experiences of others to strengthen your own resilience.

Competitive Advantage: Organizations that prioritize compliance can gain a competitive edge. Customers and partners are more likely to choose businesses that have a strong track record of compliance, as it instills confidence in their ability to deliver consistent quality and performance.

Global Expansion: For organizations operating on a global scale, compliance with international standards can be crucial. It facilitates market access and trade, as many countries require adherence to specific standards for imported goods and services. Non-compliance can be a barrier to entry into new markets.

Insurance and Risk Management: Many insurance providers take compliance with industry standards and best practices into account when assessing risk and setting premiums. Demonstrating a commitment to compliance can result in more favorable insurance terms, reducing the financial impact of potential disruptions.

Supply Chain Resilience: Supply chains are interconnected and reliant on multiple partners. Compliance with industry standards for supply chain resilience helps ensure that all parties in the supply chain are aligned in terms of risk management, reducing vulnerabilities and improving the overall resilience of the network.

Ethical and Sustainable Practices: Some regulations and standards also encompass ethical and sustainable practices, including environmental responsibility and labor rights. Compliance in these areas is not only a legal requirement but also aligns with broader societal expectations for responsible business conduct.

Crisis Preparedness: Regulations often require organizations to have crisis management and recovery plans in place. These plans are invaluable when unexpected disruptions occur, enabling organizations to respond effectively and minimize damage.

In summary, compliance with regulations and industry standards related to risk management and supply chain resilience is more than a bureaucratic exercise. It’s a strategic imperative that helps organizations protect their operations, reputation, and competitive position in an increasingly complex and unpredictable business environment. By adhering to these guidelines, organizations not only meet legal obligations but also build a foundation for long-term success and sustainability.

Explore this link for a more extensive examination of the topic: BUILDING RESILIENT SUPPLY CHAINS, REVITALIZING …

Supply chain resilience and risk management are essential components of modern business strategy. Organizations that prioritize these areas are better prepared to navigate disruptions, protect their reputation, and ultimately thrive in an increasingly complex and uncertain world. By understanding the risks, implementing proactive measures, and fostering collaboration, businesses can build resilient supply chains that withstand the test of time.

Supply chain resilience and risk management have become fundamental pillars of contemporary business strategy. As the business landscape continues to evolve in complexity and uncertainty, organizations that place a premium on these aspects are poised for success. Here’s an extended exploration of this idea:

Strategic Imperative: Supply chain resilience and risk management are no longer optional but a strategic imperative. Companies recognize that disruptions are inevitable, whether they stem from natural disasters, geopolitical shifts, or unforeseen events like the COVID-19 pandemic. By acknowledging this reality, businesses can proactively prepare for and respond to disruptions.

Holistic Approach: Effective supply chain resilience goes beyond isolated measures to encompass a holistic approach. It involves assessing risks at every stage of the supply chain, from sourcing and production to distribution and delivery. This comprehensive evaluation enables organizations to identify vulnerabilities and design robust risk mitigation strategies.

Scenario Planning: Scenario planning is a valuable tool for supply chain resilience. Companies simulate various disruption scenarios to assess their preparedness and identify potential weaknesses. This forward-looking approach helps organizations develop response plans tailored to specific challenges.

Diversification: Diversifying suppliers, sourcing regions, and transportation modes is a common strategy to enhance supply chain resilience. By reducing reliance on a single source or route, companies reduce the risk of disruptions cascading through their supply chains.

Technology Adoption: Leveraging technology and data analytics, companies gain real-time visibility into their supply chains. Predictive analytics and artificial intelligence help organizations anticipate disruptions and optimize supply chain processes. Technologies like blockchain enhance transparency and traceability.

Supplier Collaboration: Collaborative partnerships with suppliers are pivotal for resilience. Close relationships foster open communication and trust, enabling early detection of potential issues. Suppliers can become valuable allies in navigating disruptions together.

Continuous Monitoring: Supply chain monitoring should be a continuous process. Regular audits, assessments, and performance reviews help organizations stay informed about the health of their supply chains and identify areas for improvement.