Introduction

The Fourth Industrial Revolution, often referred to as Industry 4.0, is reshaping the global industrial landscape, ushering in a new era of interconnectedness, automation, and data-driven decision-making. At the forefront of this transformation stands Germany, a nation renowned for its engineering prowess and commitment to innovation. In this article, we explore how Germany is leading the charge in Industry 4.0 and the far-reaching implications of its leadership on a global scale.

The Fourth Industrial Revolution, often referred to as Industry 4.0, represents a pivotal moment in history when technology and industry converge to reshape the world as we know it. As this transformative wave sweeps across nations and sectors, one nation in particular stands out as a beacon of innovation and excellence – Germany.

Renowned for its engineering prowess and steadfast commitment to pushing the boundaries of technology, Germany finds itself at the forefront of this revolution. Its rich industrial heritage and dedication to precision engineering have laid the groundwork for a transition into a new era marked by interconnectedness, automation, and data-driven decision-making.

Within Germany’s borders, factories are evolving into smart, interconnected hubs of production. The fusion of IoT (Internet of Things) devices, artificial intelligence, and big data analytics has ushered in an era of production efficiency previously unimaginable. The German Mittelstand, a network of medium-sized enterprises that forms the backbone of the country’s economy, is embracing these innovations, ensuring that even smaller firms are not left behind in the race to Industry 4.0.

Beyond the factory floor, Germany’s commitment to education and vocational training is nurturing a skilled workforce capable of thriving in this digital age. Apprenticeships and training programs are adapting to the demands of the modern workforce, equipping individuals with the skills needed to excel in roles that were unheard of a decade ago.

Germany’s leadership in Industry 4.0 is not confined within its borders. Its influence extends globally, as German companies export their expertise and technologies to nations eager to embark on their own Industry 4.0 journeys. This exportation of knowledge and innovation solidifies Germany’s role as a global trailblazer in the Fourth Industrial Revolution.

The implications of Germany’s leadership in Industry 4.0 reach far and wide. As more countries and industries follow in its footsteps, we can anticipate a more interconnected world, where automation streamlines processes, data empowers decision-makers, and innovation drives progress. However, with this transformation comes a host of challenges, including questions about data privacy, cybersecurity, and the impact on traditional job roles. These are topics that we will delve into as we explore the profound effects of Germany’s Industry 4.0 leadership on a global scale in this article.

Don’t stop here; you can continue your exploration by following this link for more details: Reskilling and Upskilling the Future-ready Workforce for Industry 4.0 …

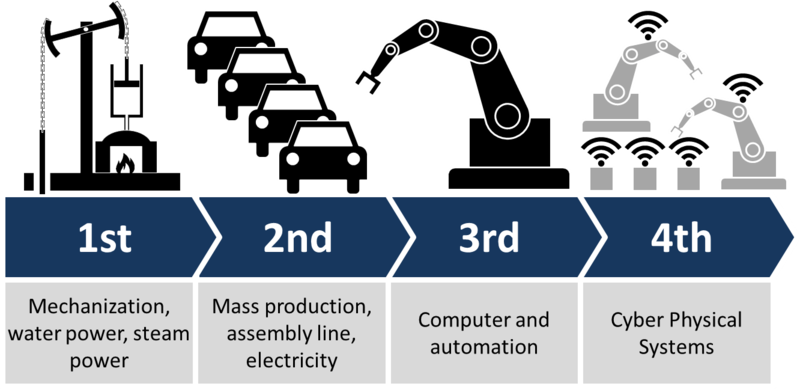

Industry 4.0 represents a paradigm shift in manufacturing and industrial processes. It is characterized by the integration of digital technologies, the Internet of Things (IoT), artificial intelligence (AI), and data analytics into every aspect of production and supply chain management. The goal is to create “smart factories” capable of optimizing operations, reducing costs, and increasing productivity.

Industry 4.0 represents a profound paradigm shift in manufacturing and industrial processes, reshaping the way we approach production and supply chain management. This transformative movement is underpinned by the seamless integration of cutting-edge digital technologies, including the Internet of Things (IoT), artificial intelligence (AI), and advanced data analytics, into every facet of industrial operations.

At its core, Industry 4.0 envisions the development of “smart factories,” which are not just automated but also intelligent and responsive. These smart factories leverage real-time data from interconnected devices and sensors to make informed decisions and optimize production processes on the fly. This agility is a game-changer in the manufacturing world, as it allows for rapid adaptation to changing market demands, unexpected disruptions, and fluctuations in resource availability.

One of the key objectives of Industry 4.0 is to enhance operational efficiency significantly. By utilizing AI-driven predictive maintenance, manufacturers can foresee equipment failures before they occur, thereby reducing downtime and maintenance costs. Additionally, the ability to monitor and fine-tune production processes in real-time ensures that resources are utilized more efficiently, leading to substantial cost savings.

Moreover, Industry 4.0 is a catalyst for innovation. By harnessing the power of data analytics, companies can gain deeper insights into consumer preferences and market trends. This information can be used to develop customized products, improve existing ones, and enhance overall customer experiences. The result is not just increased productivity but also a competitive edge in the global market.

However, the journey towards Industry 4.0 is not without its challenges. It requires substantial investments in technology infrastructure and a skilled workforce capable of operating and maintaining these advanced systems. Moreover, there are crucial considerations surrounding data security and privacy in an interconnected environment. Manufacturers must prioritize cybersecurity measures to safeguard sensitive information from potential threats.

In conclusion, Industry 4.0 heralds a new era of manufacturing and supply chain management. It is a convergence of digital technologies that promises smarter, more efficient, and innovative industrial processes. As companies continue to embrace and adapt to this paradigm shift, they stand to reap the rewards of increased productivity, reduced costs, and enhanced competitiveness in a rapidly evolving global landscape.

To expand your knowledge on this subject, make sure to read on at this location: Industry 4.0, a revolution that requires technology and national …

Germany’s leadership in Industry 4.0 is a natural extension of its historical commitment to engineering excellence. Several factors contribute to its pioneering role:

Germany’s leadership in Industry 4.0 is a natural extension of its historical commitment to engineering excellence, which has been cultivated over centuries. Several factors contribute to its pioneering role, including a robust education system emphasizing STEM disciplines, a strong culture of innovation, a tradition of precision craftsmanship, and a thriving ecosystem of research and development. This rich tapestry of elements has woven together to position Germany at the forefront of the fourth industrial revolution, shaping the future of manufacturing and technology worldwide.

Looking for more insights? You’ll find them right here in our extended coverage: Digital Transformation Monitor – Germany: Industrie 4.0

Germany’s leadership in Industry 4.0 extends its influence far beyond its borders:

Germany’s leadership in Industry 4.0 extends its influence far beyond its borders, shaping the future of global manufacturing and technology. This forward-thinking approach to industrial innovation not only positions Germany as a trailblazer but also serves as a beacon for other nations aspiring to harness the potential of the Fourth Industrial Revolution. As Germany continues to pioneer the integration of digital technologies, automation, and smart systems into its industrial processes, it paves the way for enhanced productivity, sustainability, and economic growth on a global scale. Moreover, by fostering international collaborations and knowledge-sharing, Germany’s impact resonates across industries and nations, fostering a collaborative spirit that propels the world towards a more interconnected and technologically advanced future.

For additional details, consider exploring the related content available here The Impact of the First World War and Its Implications for Europe

Conclusion

Germany’s leadership in Industry 4.0 represents a pivotal moment in the evolution of global industry. The country’s dedication to innovation, collaboration, and technological advancement is reshaping manufacturing processes, supply chains, and business models worldwide. As the Fourth Industrial Revolution continues to unfold, Germany’s influence will be felt far and wide, ushering in an era of smarter, more efficient, and sustainable industrial practices with global implications that extend beyond borders and industries.

Germany’s leadership in Industry 4.0 represents a pivotal moment in the evolution of global industry. The country’s dedication to innovation, collaboration, and technological advancement is reshaping manufacturing processes, supply chains, and business models worldwide. As the Fourth Industrial Revolution continues to unfold, Germany’s influence will be felt far and wide, ushering in an era of smarter, more efficient, and sustainable industrial practices with global implications that extend beyond borders and industries.

At the heart of Industry 4.0 is the convergence of physical and digital technologies, resulting in smart factories where machinery, processes, and data are seamlessly integrated. Germany’s commitment to this transformation is evident in its “Made in Germany 4.0” initiative, which promotes the adoption of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics in manufacturing. German companies are not just embracing these technologies; they are pioneering their application, setting the standard for what smart manufacturing can achieve.

One of the key aspects of Germany’s leadership in Industry 4.0 is its emphasis on collaboration. German businesses, both large and small, often work closely with research institutions and government agencies to drive innovation. This collaborative ecosystem fosters the rapid development and implementation of cutting-edge technologies, ensuring that the benefits of Industry 4.0 are accessible to a wide range of industries and players.

Germany’s dedication to technological advancement extends to its commitment to sustainability. Industry 4.0 is not just about efficiency; it’s also about reducing environmental impact. German manufacturers are using data-driven insights to optimize energy consumption, minimize waste, and implement eco-friendly production processes. This environmentally conscious approach aligns with global efforts to combat climate change and sets a precedent for responsible industrial practices worldwide.

The influence of Germany’s Industry 4.0 leadership reaches far beyond its borders. Many countries are looking to Germany as a model for their own industrial transformation efforts. German-made manufacturing technologies and best practices are in high demand globally, contributing to export growth and economic stability. As other nations adopt these technologies and practices, the ripple effect will be felt across international supply chains, fostering greater efficiency and transparency.

Moreover, the principles of Industry 4.0 are not limited to manufacturing. They are permeating various industries, from healthcare to logistics to agriculture. This cross-sectoral impact is creating new opportunities for innovation and economic growth worldwide. Germany’s pioneering role in Industry 4.0 serves as a beacon for industries across the globe, inspiring them to embrace digital transformation and adapt to the changing landscape of the Fourth Industrial Revolution.

In conclusion, Germany’s leadership in Industry 4.0 is reshaping the global industrial landscape in profound ways. Through innovation, collaboration, and a commitment to sustainability, Germany is not only revolutionizing manufacturing but also inspiring a worldwide shift toward smarter, more efficient, and environmentally responsible industrial practices. As we move further into the Fourth Industrial Revolution, Germany’s influence will continue to be a driving force in shaping the future of industries and economies worldwide.

Additionally, you can find further information on this topic by visiting this page: The Future of Jobs Report 2020

More links

Should you desire more in-depth information, it’s available for your perusal on this page: Digital Transformation Monitor – Germany: Industrie 4.0