Introduction

In an era marked by a growing global demand for sustainable energy solutions, Tesla’s Gigafactories have emerged as beacons of innovation in the realm of battery production. These colossal manufacturing facilities are not merely factories; they represent a vision for a cleaner, greener future.

In an age defined by an ever-increasing global demand for sustainable energy solutions, Tesla’s Gigafactories stand as towering symbols of innovation in the field of battery production. These colossal manufacturing facilities are far more than mere factories; they represent a visionary blueprint for a cleaner, greener future.

At the heart of Tesla’s Gigafactories lies a commitment to addressing one of the most critical challenges in transitioning to a sustainable energy ecosystem: the production of high-capacity batteries. These batteries are the lifeblood of electric vehicles and play a pivotal role in grid storage solutions. Tesla recognized early on that to accelerate the adoption of electric vehicles and renewable energy, a radical reimagining of battery production was essential.

Gigafactories are monumental in scale and ambition. They are designed to produce batteries at an unprecedented volume, driving down production costs and making electric vehicles more accessible to a broader range of consumers. By achieving economies of scale, Tesla not only ensures that its vehicles are competitively priced but also contributes to the broader affordability of electric mobility for everyone.

Moreover, these facilities are strategically located across the globe, serving as regional hubs for both production and innovation. They’re not just about meeting current demand; they are forward-looking, anticipating the future needs of a world transitioning to sustainable energy sources. This global presence also reduces the carbon footprint associated with transportation, as batteries can be produced closer to their intended markets.

Beyond the sheer scale of production, Gigafactories are also hotbeds of research and development. Tesla continually invests in advancing battery technology, seeking ways to increase energy density, improve longevity, and reduce raw material dependency. This commitment to innovation has far-reaching implications, as it not only benefits Tesla’s products but also influences the broader renewable energy landscape.

Tesla’s Gigafactories represent more than a manufacturing shift; they embody a paradigm shift. They are icons of sustainability, showcasing how the marriage of cutting-edge technology, sustainable practices, and sheer determination can redefine an industry. In a world where clean energy solutions are not just a preference but a necessity, Gigafactories serve as guiding lights, illuminating the path toward a future where renewable energy and electric transportation are not just aspirations but accessible realities for all.

As global demand for sustainable energy continues to surge, Tesla’s commitment to innovation in battery production through its Gigafactories stands as a testament to the company’s unwavering dedication to a greener future. These monumental facilities not only manufacture batteries; they manufacture hope, progress, and a vision for a world where sustainability and technological advancement unite for the benefit of all.

To delve further into this matter, we encourage you to check out the additional resources provided here: The Story Behind Tesla’s Success (TSLA)

The term “Gigafactory” was coined by Tesla to describe its ambitious plan to build enormous battery production plants capable of producing gigawatt-hours (GWh) of batteries annually. The idea behind these Gigafactories was to scale up battery production to meet the rising demand for electric vehicles (EVs) and energy storage systems, while simultaneously driving down the cost of batteries.

The birth of the term “Gigafactory” within the context of Tesla represents a pivotal moment in the trajectory of the electric vehicle (EV) and renewable energy industries. Conceived as a symbol of ambition and innovation, these Gigafactories are more than just production plants; they are monuments to the transformation of entire sectors.

At their core, Gigafactories embody Tesla’s visionary strategy to revolutionize the energy landscape. By conceptualizing and implementing these colossal facilities, Tesla aimed to tackle two fundamental challenges head-on.

Firstly, the primary objective was to address the surging demand for EVs and energy storage systems. As the world began to recognize the imperative of transitioning away from fossil fuels, the demand for clean energy solutions skyrocketed. Tesla, with its commitment to sustainability and cutting-edge technology, found itself at the forefront of this shift. The Gigafactories, with their capability to churn out gigawatt-hours of batteries annually, were designed to be the engines that powered this green revolution.

Secondly, and perhaps equally significant, was Tesla’s determination to drive down the cost of batteries. Batteries have long been a key component in the cost structure of EVs and energy storage systems. Reducing the cost of batteries was not merely an economic goal; it was a strategic move to make sustainable energy more accessible to a broader spectrum of consumers. By achieving economies of scale through the Gigafactory model, Tesla aimed to make clean energy solutions more affordable, thereby accelerating their adoption.

The impact of the Gigafactory concept extended far beyond Tesla itself. It triggered a wave of investment and innovation within the battery industry, encouraging other companies to explore similar large-scale production facilities. This competitive landscape spurred advancements in battery technology, resulting in improved energy density, longer battery life, and faster charging times.

Furthermore, the Gigafactories created job opportunities and stimulated economic growth in regions fortunate enough to host these colossal facilities. These plants, often the largest of their kind, became symbols of progress and prosperity in their respective communities.

As Tesla continued to expand its Gigafactory network across the globe, the company’s commitment to sustainability remained unwavering. These factories were not just about meeting present demand but also about laying the foundation for a future powered by clean energy. The Gigafactories represent a paradigm shift in how we produce, store, and consume energy, setting the stage for a world where sustainability is not just a goal but a reality. They are a testament to the power of innovation, scale, and unwavering dedication to a cleaner, more sustainable future.

You can also read more about this here: Vertically Integrated Supply Chain of Batteries, Electric Vehicles …

Tesla’s Gigafactory network spans the globe, with key locations in Nevada, Shanghai, Berlin, and Texas, and plans for more in the future. These locations were strategically chosen to reduce transportation costs and emissions associated with shipping batteries over long distances.

Tesla’s strategic establishment of the Gigafactory network reflects a forward-thinking approach that extends beyond the mere production of electric vehicles and batteries. Each Gigafactory location represents a carefully calculated move aimed at optimizing efficiency, reducing environmental impact, and bolstering Tesla’s position in the global electric vehicle market.

Nevada, home to the Gigafactory 1, serves as the hub for battery cell and module production. This facility not only produces a significant portion of the world’s lithium-ion batteries but also plays a pivotal role in advancing battery technology. With its massive scale and efficient production processes, the Nevada Gigafactory has become a linchpin in Tesla’s ability to manufacture electric vehicles at scale.

On the other side of the world, the Gigafactory in Shanghai, China, exemplifies Tesla’s commitment to tapping into global markets. By establishing a manufacturing presence in China, Tesla has not only reduced production costs but has also sidestepped import tariffs, making its vehicles more affordable and competitive in the Chinese market, which is the largest in the world. This strategic move has solidified Tesla’s standing as a major player in the global electric vehicle industry.

Berlin, Germany, represents Tesla’s gateway to the heart of Europe. With the construction of Gigafactory Berlin-Brandenburg, Tesla is positioning itself to meet the growing demand for electric vehicles in Europe while minimizing shipping distances and reducing carbon emissions associated with transportation. This facility is set to produce batteries, powertrains, and vehicles, enhancing Tesla’s capacity to serve the European market efficiently.

The Gigafactory in Texas, known as Giga Texas, represents an expansion of Tesla’s presence in the United States. It focuses on the production of the Cybertruck, Tesla’s all-electric pickup, and serves as a strategic move to tap into the booming market for electric trucks. By manufacturing the Cybertruck closer to its North American customer base, Tesla can reduce delivery times and logistics costs.

Beyond these established Gigafactories, Tesla continues to look to the future. Plans for additional Gigafactory locations are on the horizon, each strategically chosen to serve emerging markets and reduce the environmental footprint associated with transporting vehicles and batteries over long distances.

In conclusion, Tesla’s Gigafactory network is a testament to the company’s commitment to sustainability, efficiency, and global reach. These strategically located manufacturing hubs not only enable Tesla to produce electric vehicles and batteries at scale but also underscore the company’s dedication to reducing transportation costs and emissions. As Tesla continues to expand its footprint, it is not only shaping the future of electric mobility but also redefining the automotive industry’s approach to sustainable and efficient manufacturing.

Additionally, you can find further information on this topic by visiting this page: Gigafactory Logistics in Space and Time: Tesla’s Fourth Gigafactory …

One of the defining features of Tesla’s Gigafactories is their commitment to sustainability. Each facility is designed to operate on 100% renewable energy. Solar panels and wind turbines adorn the roofs, and advanced energy storage systems ensure a continuous supply of clean power. This approach not only reduces the carbon footprint of battery production but also sets an example for sustainable industrial practices.

Tesla’s Gigafactories stand as beacons of sustainability in the industrial landscape, setting new standards for environmentally conscious manufacturing. Their unwavering commitment to sustainability goes beyond mere rhetoric, shaping every facet of their operations.

At the core of this commitment is the resolute choice to power each Gigafactory with 100% renewable energy. Solar panels, meticulously aligned to capture sunlight, adorn vast expanses of rooftop space. These solar arrays transform each factory into a clean energy powerhouse, harnessing the sun’s abundant power to meet a substantial portion of their energy needs. Coupled with wind turbines, these facilities showcase a harmonious blend of renewable resources, ensuring a continuous and reliable supply of clean power.

Perhaps even more remarkable is the advanced energy storage systems deployed within these Gigafactories. Tesla’s own energy storage products, like the Powerwall and Powerpack, play a crucial role in balancing energy generation and consumption. Excess energy generated during peak sunlight hours is stored, ready to be utilized during periods of high demand or when the sun sets. This intelligent use of energy storage not only enhances the stability of the grid but also maximizes the utilization of clean energy, reducing reliance on fossil fuels.

The impact of Tesla’s sustainability practices extends far beyond the boundaries of their facilities. By operating on 100% renewable energy, they are not only reducing their own carbon footprint but also sending a powerful message to the industrial world. They are proving that large-scale manufacturing can coexist harmoniously with the environment, dispelling the myth that sustainability comes at the cost of economic viability.

Tesla’s commitment to sustainability in its Gigafactories is a testament to its broader mission of accelerating the world’s transition to sustainable energy. It serves as a living demonstration of the possibilities that renewable energy and innovative technology can offer. As the global community grapples with the urgent need to address climate change, these Gigafactories stand as inspirational examples of what can be achieved when sustainability is at the heart of industrial practices.

In conclusion, Tesla’s Gigafactories are not just manufacturing facilities; they are symbols of a sustainable future. They exemplify the profound impact that one company’s dedication to clean energy and responsible practices can have on an industry, a region, and the world. As they continue to expand and evolve, these facilities reinforce the idea that sustainability is not a choice but an imperative for the betterment of our planet and future generations.

For additional details, consider exploring the related content available here Vertically Integrated Supply Chain of Batteries, Electric Vehicles …

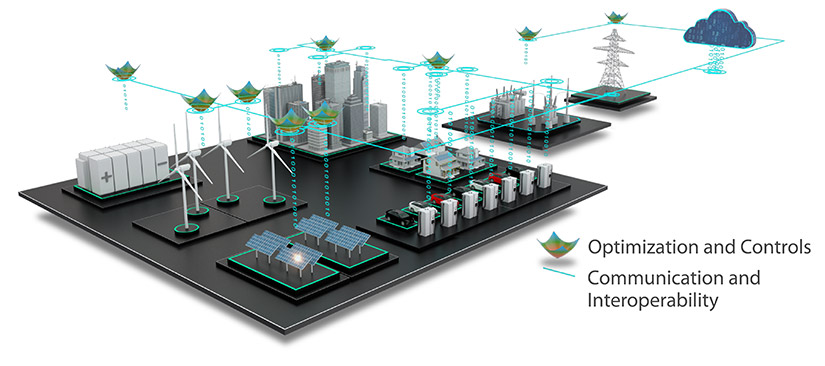

Tesla’s Gigafactories are not just about producing batteries; they represent a shift toward a sustainable energy ecosystem. The batteries manufactured in these facilities power not only Tesla’s renowned electric vehicles but also residential and commercial energy storage solutions. These batteries are vital for storing intermittent renewable energy sources like solar and wind, making them available when needed most.

Tesla’s Gigafactories, often lauded for their role in producing cutting-edge batteries, are at the forefront of a more profound transformation – the evolution toward a sustainable energy ecosystem. Beyond being mere production facilities, these vast complexes are integral to reshaping how we generate, store, and utilize energy in a sustainable and environmentally friendly manner.

At the heart of this transformation lies the batteries themselves. Tesla’s advanced battery technology is not confined solely to powering their renowned electric vehicles. Instead, it extends its reach to encompass residential and commercial energy storage solutions. These batteries are the linchpin of a sustainable future, facilitating the seamless integration of intermittent renewable energy sources like solar and wind into our daily lives.

Consider the impact on residential settings. With Tesla’s home energy storage solutions, households can capture excess energy generated by their solar panels during the day and store it for use during the night or during periods of inclement weather. This not only reduces reliance on the grid but also enhances energy self-sufficiency and resilience.

In commercial applications, Tesla’s batteries play a vital role in ensuring uninterrupted power supply. They provide businesses with the means to store surplus energy generated during off-peak hours and deploy it during peak demand, reducing energy costs and enhancing grid stability.

Crucially, these batteries serve as a linchpin for the broader integration of renewable energy into our energy mix. Solar panels and wind turbines, while clean and abundant sources of energy, are inherently intermittent. The sun doesn’t shine at night, and the wind isn’t constant. Tesla’s batteries bridge this gap by storing excess energy when it’s abundant and making it available when needed most.

In essence, Tesla’s Gigafactories and their associated battery technology are catalysts for a paradigm shift in how we think about energy. They empower individuals, businesses, and communities to not only reduce their carbon footprint but also take control of their energy destiny. As the world grapples with the urgency of climate change and the need to transition to sustainable energy sources, Tesla’s vision and innovation offer a ray of hope and a blueprint for a cleaner, greener, and more sustainable future.

Don’t stop here; you can continue your exploration by following this link for more details: Tesla 2020 Impact Report

By operating at such a colossal scale, Tesla has been able to drive down the cost of battery production significantly. This cost reduction is crucial for making EVs more affordable and accelerating the transition to clean transportation.

Tesla’s Gigafactories represent a monumental leap in the world of sustainable battery production. These state-of-the-art facilities not only produce batteries at an unprecedented scale but also integrate renewable energy sources like solar and wind to power their operations. This commitment to sustainability not only reduces the environmental impact of battery manufacturing but also sets a pioneering example for the broader industry.

At the heart of Tesla’s Gigafactory approach is the pursuit of efficiency. These facilities leverage cutting-edge automation, advanced robotics, and smart manufacturing techniques to streamline the production process. By minimizing waste, optimizing energy consumption, and maximizing output, Tesla can produce batteries more efficiently than ever before.

Furthermore, Tesla’s Gigafactories are strategically located in regions with abundant access to raw materials, reducing transportation costs and environmental emissions associated with sourcing materials from distant locations. This localized approach to production minimizes the carbon footprint of battery manufacturing.

Tesla’s Gigafactories are not just about mass production; they are also hubs of innovation. These facilities serve as research and development centers where engineers and scientists continually work to improve battery technology. With each iteration, Tesla’s batteries become more energy-dense, longer-lasting, and cost-effective, driving the evolution of electric vehicles.

Perhaps one of the most remarkable aspects of Tesla’s Gigafactories is their potential to disrupt the entire energy ecosystem. These facilities aim to operate on 100% renewable energy, utilizing on-site solar panels, wind turbines, and energy storage solutions. Excess energy generated during the day can be stored in Tesla’s Powerpacks and Powerwalls for use during non-sunlight hours. This integration of renewable energy into battery production not only reduces the environmental impact but also contributes to a cleaner and more sustainable energy grid.

In essence, Tesla’s Gigafactories are not just manufacturing plants; they are beacons of innovation, sustainability, and progress. They represent a bold vision for the future, where the production of clean energy and the transformation of transportation are tightly intertwined. As these Gigafactories continue to expand and multiply, they are poised to play a pivotal role in shaping a more sustainable and electrified world.

Should you desire more in-depth information, it’s available for your perusal on this page: Tesla 2020 Impact Report

Beyond their contributions to clean energy, Tesla’s Gigafactories have also had a positive impact on local economies. These facilities create thousands of jobs and stimulate economic growth in the regions where they are located, demonstrating the potential for sustainable practices to drive economic development.

Beyond their contributions to clean energy, Tesla’s Gigafactories have emerged as beacons of economic vitality within the regions they call home. These state-of-the-art facilities are not just hubs of innovation; they are powerful engines of job creation and economic growth. Here’s how Tesla’s Gigafactories are making a tangible difference in local economies:

Job Creation on a Massive Scale

Tesla’s Gigafactories are colossal in scale, and so too are the employment opportunities they generate. These facilities hire thousands of workers, spanning a wide range of roles from engineers and technicians to production line workers and administrative staff. The influx of employment opportunities not only reduces local unemployment rates but also bolsters the overall economic stability of the region.

A Magnet for Skilled Talent

Tesla’s commitment to cutting-edge technology and sustainability has turned its Gigafactories into magnets for skilled talent. People from diverse backgrounds, including engineering, manufacturing, and renewable energy sectors, are drawn to these facilities to contribute to a more sustainable future. This influx of skilled professionals elevates the local talent pool, which can have a positive ripple effect on other industries and businesses in the area.

Supply Chain Stimulus

The presence of Gigafactories has a broader impact on the local supply chain. To meet the production demands of these massive facilities, numerous local suppliers and service providers often emerge or expand. This not only fosters entrepreneurial opportunities but also stimulates economic growth for these smaller businesses, creating a web of economic interdependence.

Education and Training Programs

Tesla frequently collaborates with local educational institutions to create training programs tailored to the specific needs of its Gigafactories. These programs not only ensure a skilled workforce but also enhance the educational infrastructure in the region. They provide pathways for individuals to acquire valuable technical skills, further increasing their employability and overall economic prospects.

Sustainable Business Practices

Tesla’s Gigafactories are not just about large-scale production; they are also exemplars of sustainable business practices. These facilities often incorporate renewable energy sources, energy-efficient technologies, and waste reduction strategies. This commitment to sustainability extends to the local community, inspiring other businesses to adopt eco-friendly practices and reduce their environmental footprint.

Community Investment

Tesla recognizes the importance of being a good neighbor. The company frequently invests in community development initiatives, ranging from local infrastructure improvements to support for community organizations. These investments not only enhance the quality of life for residents but also strengthen the bond between Tesla and the communities where its Gigafactories are located.

In conclusion, Tesla’s Gigafactories represent far more than manufacturing hubs for electric vehicles and clean energy solutions. They are catalysts for economic revitalization, job creation, and sustainable development in their respective regions. By demonstrating that environmentally responsible practices can drive economic prosperity, Tesla’s Gigafactories set a powerful example for other industries and underline the potential for sustainability to be a cornerstone of future economic growth.

Should you desire more in-depth information, it’s available for your perusal on this page: Gigafactory Logistics in Space and Time: Tesla’s Fourth Gigafactory …

Tesla’s Gigafactories have not been without their challenges, including supply chain issues and environmental concerns. However, the company’s commitment to sustainability and continuous improvement means that these challenges are addressed head-on, with an eye toward a more sustainable future.

Tesla’s ambitious Gigafactories, sprawling hubs of innovation and production, have undeniably faced their share of challenges. From supply chain disruptions to environmental concerns, the road to building these mega-factories has been anything but smooth. However, what truly sets Tesla apart is its unwavering commitment to addressing these challenges with a proactive approach that aligns with its overarching mission of sustainability and continuous improvement.

Supply chain issues, a common hurdle in manufacturing, have impacted Tesla as they have other companies. The intricate web of global suppliers and logistics can be susceptible to disruptions, affecting production timelines and causing delays. Yet, Tesla’s response to these challenges has been marked by adaptability and resilience. The company has displayed a remarkable ability to pivot, adjusting strategies and seeking alternative solutions to mitigate supply chain bottlenecks. This agility has allowed Tesla to weather storms and maintain its position as a leader in the EV industry.

Environmental concerns have also been part of the Gigafactory narrative. Building and operating factories on such a massive scale inevitably raise questions about their ecological footprint. Tesla acknowledges these concerns and has taken concrete steps to minimize its environmental impact. From incorporating renewable energy sources and sustainable materials into the construction process to implementing innovative waste management and water recycling systems, Tesla strives to ensure that its Gigafactories adhere to rigorous environmental standards. The ultimate goal is to not only meet regulatory requirements but to exceed them, setting new benchmarks for eco-friendly manufacturing.

Tesla’s commitment to sustainability is the driving force behind its response to these challenges. The company’s ethos is not just about producing electric vehicles but about reimagining the entire automotive industry as part of a broader commitment to a greener future. The challenges encountered along the way are viewed not as roadblocks but as opportunities for improvement and innovation.

In essence, Tesla’s approach to its Gigafactories reflects a holistic vision of sustainable manufacturing. These challenges, while significant, are seen as integral to the journey toward a more sustainable future. By addressing them head-on and striving for continuous improvement, Tesla sets a powerful example for the industry and underscores its unwavering commitment to creating a world where sustainability and innovation go hand in hand.

As Tesla continues to expand its manufacturing capabilities and build Gigafactories worldwide, it does so with a firm belief that challenges can be transformed into opportunities. The company’s resilience, adaptability, and commitment to sustainability not only drive its success but also inspire others to join the mission of accelerating the world’s transition to sustainable energy. Tesla’s Gigafactories are more than just production centers; they are beacons of innovation and sustainability in a world that increasingly recognizes the urgent need for both.

To delve further into this matter, we encourage you to check out the additional resources provided here: Does Elon Musk Have a Strategy?

Conclusion

In conclusion, Tesla’s Gigafactories represent a paradigm shift in sustainable battery production. They are not only essential for powering the EV revolution but also serve as beacons of hope for a future where clean, renewable energy sources power our lives. As Tesla continues to expand its Gigafactory network and refine its processes, the impact on sustainable battery production and the broader clean energy landscape will undoubtedly be profound.

In summary, Tesla’s Gigafactories are not just manufacturing facilities; they are the embodiment of a visionary approach to sustainable energy and clean technology. These colossal complexes are at the forefront of the global push towards a more sustainable future, where electric vehicles and renewable energy play a central role in reducing carbon emissions and mitigating the effects of climate change.

At their core, Tesla’s Gigafactories are crucial to the electric vehicle revolution. They churn out the advanced batteries that power Tesla’s vehicles, making electric mobility a reality for people around the world. By producing these batteries efficiently and at scale, Tesla has played a pivotal role in making electric vehicles more accessible and attractive to consumers, accelerating the transition away from fossil fuels.

However, the impact of Tesla’s Gigafactories transcends the automotive sector. They symbolize a broader commitment to sustainable energy solutions. Gigafactories not only produce batteries for vehicles but also for energy storage solutions like the Powerwall and Powerpack, enabling individuals and businesses to harness renewable energy sources more effectively and reduce their reliance on conventional power grids.

Moreover, Tesla’s dedication to sustainability extends to the very processes within these Gigafactories. The company strives for a zero-emissions future in manufacturing, aiming to use renewable energy sources like solar and wind to power its operations. The Gigafactories are not just places of production; they are models of environmentally responsible manufacturing practices, setting a high standard for the industry.

As Tesla continues to expand its Gigafactory network and refines its production processes, the positive impact on sustainable battery production and the broader clean energy landscape will undoubtedly be profound. These facilities are not just beacons of hope; they are engines of change that are propelling us towards a future where clean, renewable energy sources power our lives, and sustainable transportation becomes the norm.

In essence, Tesla’s Gigafactories represent a powerful fusion of innovation, sustainability, and ambition. They remind us that addressing the pressing challenges of our time, such as climate change and environmental degradation, requires not just revolutionary technology but also a fundamental shift in how we produce and consume energy. Tesla’s Gigafactories are leading the way towards that brighter, cleaner future, and their impact will resonate far beyond the boundaries of their colossal walls.

Looking for more insights? You’ll find them right here in our extended coverage: Tesla 2020 Impact Report

More links

Explore this link for a more extensive examination of the topic: Vertically Integrated Supply Chain of Batteries, Electric Vehicles …