Introduction

The pursuit of improved engine efficiency, power, and reduced emissions has led to significant advancements in automotive technology. Among these innovations, Variable Valve Timing (VVT) and Variable Valve Lift (VVL) stand out as pivotal components that enhance engine performance and efficiency. In this article, we will delve into the world of VVT and VVL, exploring their principles, benefits, and their impact on the automotive industry.

The automotive industry has been on a relentless quest for continuous improvement in engine efficiency, power, and environmental sustainability. This pursuit has given rise to a host of innovative technologies, and two standout advancements are Variable Valve Timing (VVT) and Variable Valve Lift (VVL). These technologies have revolutionized engine performance and efficiency, ushering in a new era of automotive engineering excellence. In this article, we will embark on a comprehensive exploration of VVT and VVL, delving into their underlying principles, the wide-ranging benefits they offer, and their profound impact on the automotive landscape.

The Principles of Variable Valve Timing (VVT) and Variable Valve Lift (VVL)

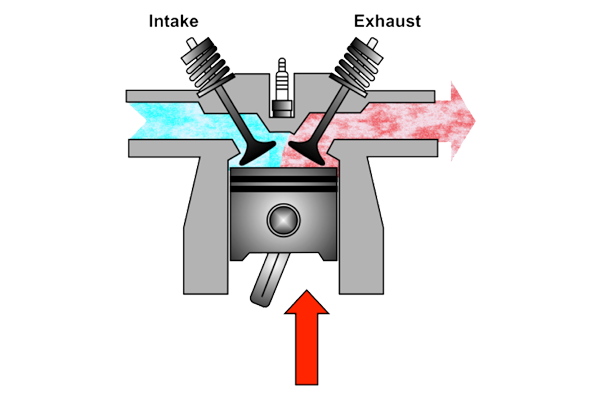

At the heart of VVT and VVL lies the fundamental principle of optimizing the timing and lift of an engine’s intake and exhaust valves. Traditionally, engines have fixed valve timing and lift profiles that cater to a specific range of operating conditions. However, this rigid approach often results in compromises. For instance, an engine designed for high-end power may sacrifice low-end torque, and vice versa.

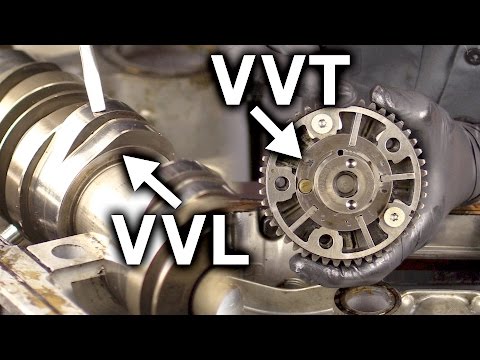

VVT and VVL technologies break free from these constraints by providing dynamic control over valve operation. VVT primarily focuses on adjusting the timing of valve opening and closing, while VVL adds another layer of flexibility by modulating the lift or height of the valves. These adjustments are orchestrated in real-time, responding to various parameters such as engine speed, load, temperature, and throttle position.

The Multifaceted Benefits of VVT and VVL

The incorporation of VVT and VVL into engine design yields a multitude of advantages that reverberate throughout the automotive realm:

Enhanced Efficiency: One of the paramount benefits of VVT and VVL is improved fuel efficiency. By optimizing valve timing and lift, engines can operate more efficiently across a broader range of conditions. This efficiency translates into reduced fuel consumption and lower emissions, aligning with stringent environmental regulations and consumer demands for greener vehicles.

Power and Torque: VVT and VVL enable engines to deliver superior power and torque characteristics. Whether it’s the spirited acceleration of a sports car or the low-end grunt of a truck, these technologies provide the flexibility to tailor performance to specific needs. The result is an exhilarating driving experience without compromising on fuel economy.

Reduced Emissions: Combustion efficiency is a key contributor to emission reduction. By optimizing valve timing and lift, VVT and VVL technologies promote more complete combustion, reducing the release of harmful pollutants. This is particularly significant in the context of increasingly stringent emissions standards worldwide.

Smooth and Quiet Operation: VVT and VVL contribute to smoother and quieter engine operation. Precise control over valve actuation minimizes vibration and noise, enhancing passenger comfort and overall refinement. Noise, vibration, and harshness (NVH) levels are notably improved, elevating the driving experience.

Adaptability: Engines equipped with VVT and VVL can adapt seamlessly to varying driving conditions. Whether cruising on the highway, tackling city traffic, or accelerating aggressively, these technologies ensure that the engine optimally performs in each scenario. This adaptability is especially valuable in modern, multifaceted driving environments.

Reliability: The implementation of VVT and VVL has led to more reliable engine designs. These technologies have undergone extensive testing and refinement, resulting in robust and durable systems that withstand the rigors of daily use.

Impact on the Automotive Industry

The adoption of VVT and VVL has had a profound and lasting impact on the automotive industry. These technologies have become ubiquitous, finding their way into an array of vehicles, from compact cars to high-performance sports cars and even hybrid powertrains. They have allowed automakers to strike an optimal balance between power, efficiency, and environmental responsibility.

Moreover, VVT and VVL have played a crucial role in shaping the industry’s response to evolving regulatory requirements and consumer preferences. As emissions standards become increasingly stringent and the demand for more eco-friendly vehicles grows, these technologies provide a critical toolset for manufacturers to meet these challenges head-on.

In conclusion, Variable Valve Timing (VVT) and Variable Valve Lift (VVL) represent transformative advancements in automotive technology. These dynamic valve control systems epitomize the industry’s commitment to achieving the elusive trifecta of improved efficiency, enhanced performance, and reduced emissions. As we delve deeper into the world of VVT and VVL, we will uncover the intricate mechanisms, real-world applications, and the bright future that these technologies hold for the automotive landscape.

You can also read more about this here: Performance estimation of an engine with magnetorheological …

Variable Valve Timing, commonly referred to as VVT, is a technology that allows an engine’s intake and exhaust valves to open and close at different times during the engine’s operation. This dynamic adjustment optimizes engine performance under varying conditions. Here’s how VVT works:

Variable Valve Timing (VVT), often abbreviated as VVT, represents a sophisticated engineering innovation that breathes flexibility and efficiency into the heart of an engine. At its core, VVT is all about optimizing the timing of a vehicle’s intake and exhaust valves, a dynamic orchestration that adapts seamlessly to a myriad of driving scenarios.

Precision Timing Control: VVT systems achieve their magic through precision timing control. In a traditional engine, valve timing is fixed, optimized for a specific RPM range. However, real-world driving demands versatility. VVT introduces variability by enabling the engine management system to adjust the timing of the valves continually.

Enhancing Low-End Torque: One of the primary advantages of VVT is its ability to boost low-end torque. At lower engine speeds, such as during idle or initial acceleration, VVT technology optimizes valve timing for efficient air intake and combustion, resulting in more accessible and responsive torque. This translates into improved drivability, especially in stop-and-go traffic or during quick getaways from traffic lights.

Maximizing High-End Power: Conversely, when the driver calls for more power, such as during highway passing maneuvers, VVT adapts by altering valve timing to optimize airflow at higher RPMs. This shift in timing ensures that the engine can breathe more freely, generating the maximum amount of power and torque available, without sacrificing efficiency.

Improved Fuel Efficiency: VVT technology also plays a pivotal role in enhancing fuel efficiency. By optimizing valve timing based on load and speed, the engine operates with a leaner air-fuel mixture when cruising, reducing fuel consumption. This efficiency boost is especially evident in modern engines, where VVT is combined with other technologies like direct fuel injection and cylinder deactivation.

Emissions Reduction: The fine-tuned control of VVT doesn’t just benefit performance and efficiency; it also contributes to reduced emissions. The ability to precisely manage the combustion process means that engines equipped with VVT can operate with greater combustion efficiency, minimizing harmful emissions.

Versatility for All Applications: VVT isn’t exclusive to a particular type of engine or vehicle. It has found its way into a wide spectrum of applications, from small, fuel-efficient commuter cars to high-performance sports cars and even heavy-duty trucks. This adaptability underscores the versatility and effectiveness of VVT technology across diverse automotive segments.

Continuous Evolution: The world of VVT technology is in a constant state of evolution. Engineers are continually refining these systems, integrating them with other advanced technologies like variable valve lift and cylinder deactivation. This ongoing development ensures that VVT remains at the forefront of enhancing engine performance, efficiency, and environmental responsibility.

In summary, Variable Valve Timing (VVT) is a testament to the intricate and dynamic nature of modern engine technology. Its ability to adapt valve timing to varying conditions delivers tangible benefits in terms of torque, power, fuel efficiency, and reduced emissions. As automotive engineering continues to advance, VVT remains a pivotal component in the pursuit of both performance and sustainability in the ever-evolving world of transportation.

Should you desire more in-depth information, it’s available for your perusal on this page: ASM Gasoline Engine InCylinder

In a traditional engine, valve timing is fixed, which means the valves open and close at set intervals regardless of engine speed or load. VVT systems, however, use hydraulic, electronic, or mechanical mechanisms to adjust the timing of the valves’ operation.

In a traditional engine, valve timing is fixed, which means the valves open and close at set intervals regardless of engine speed or load. This rigid approach has limitations in terms of efficiency and performance. However, Variable Valve Timing (VVT) systems have revolutionized internal combustion engines by introducing dynamic control over valve operation.

Optimized Efficiency: VVT systems adapt to changing driving conditions, allowing the engine to operate more efficiently across a broader range of RPMs. At low speeds, VVT can delay valve closing to enhance combustion, improving torque and fuel economy. Conversely, at high speeds, it can advance valve closing for increased power output. This flexibility results in a well-balanced engine that delivers both efficiency and performance.

Reduced Emissions: By optimizing valve timing, VVT systems promote cleaner combustion. They help reduce emissions of harmful pollutants like nitrogen oxides (NOx) and unburned hydrocarbons. This aligns with stringent emissions standards and contributes to a cleaner environment.

Enhanced Power: VVT isn’t just about efficiency; it’s also about unlocking additional power when needed. Engines equipped with VVT can harness more energy from each combustion cycle, translating into higher horsepower and improved acceleration. This capability is particularly valuable in performance-oriented vehicles.

Smooth and Responsive Driving: VVT systems improve throttle response and drivability. The ability to adjust valve timing on the fly ensures smoother transitions between different driving scenarios, such as accelerating from a standstill, cruising on the highway, or climbing steep hills. Drivers experience a more responsive and enjoyable driving experience.

Cold Start Efficiency: During cold starts, VVT systems can keep valves open longer to warm up the engine more quickly. This reduces cold-start emissions and minimizes wear and tear on the engine, enhancing its longevity.

Reduced Knocking: By optimizing combustion, VVT helps reduce engine knocking or pinging, which can occur when fuel ignites prematurely. Knocking can damage the engine over time, and VVT mitigates this issue, ensuring smoother and quieter operation.

Adaptability to Advanced Technologies: VVT systems synergize with other advanced engine technologies, such as direct injection and turbocharging. This combination maximizes the benefits of these technologies, resulting in engines that are both powerful and efficient.

Environmental Stewardship: VVT contributes to environmental sustainability by promoting more efficient fuel consumption and reducing emissions. As the automotive industry pivots toward electrification and cleaner technologies, VVT remains a valuable tool for improving the efficiency of internal combustion engines in the interim.

In summary, Variable Valve Timing (VVT) is a transformative technology that empowers internal combustion engines to adapt to a wide range of driving conditions. Its ability to optimize valve timing enhances efficiency, reduces emissions, and boosts performance. As automotive technology continues to evolve, VVT remains a critical component in the pursuit of more sustainable and responsive engines.

Don’t stop here; you can continue your exploration by following this link for more details: Performance and power consumption optimization of a hydraulic …

Improved Power and Torque: VVT optimizes the engine’s power output by adjusting valve timing to match the engine’s speed and load. This results in increased torque at lower RPMs and more power at higher RPMs.Enhanced Fuel Efficiency: VVT can improve fuel efficiency by ensuring that the engine operates at its most efficient point across different driving conditions. It reduces unnecessary fuel consumption and emissions.

Variable Valve Timing (VVT) is a technological marvel that ushers in a host of benefits, transforming the very essence of how internal combustion engines operate:

Expanded Power Band: VVT serves as a virtuoso conductor for an orchestra of engine performance. By dynamically altering valve timing, it orchestrates an extended power band that harmonizes low-end torque with high-end power. This means that whether you’re pulling away from a stoplight or overtaking on the highway, your engine delivers the right dose of power precisely when you need it. It’s this versatility that makes VVT a sought-after feature in modern engines, enhancing the overall driving experience.

Effortless Acceleration: At lower RPMs, VVT optimizes valve timing to maximize torque production. This means that when you gently press the gas pedal, you’re greeted with a surge of torque that propels the vehicle forward effortlessly. This is particularly valuable in city driving, where frequent starts and stops demand responsive acceleration without the need to downshift.

High-Revving Excitement: Conversely, as the engine revs climb, VVT ensures that the valvetrain keeps up with the pace. It optimizes valve timing for improved airflow, enabling the engine to breathe freely and unleash its full power potential at higher RPMs. This is music to the ears of performance enthusiasts who revel in the exhilaration of high-revving engines.

Fuel Efficiency Maestro: VVT isn’t just about power; it’s also a virtuoso of efficiency. By meticulously adjusting valve timing to match the engine’s operating conditions, VVT ensures that the engine runs at its peak efficiency. This meticulous management of airflow and combustion helps reduce fuel consumption, thereby stretching each gallon of fuel further. It’s an orchestra of efficiency that harmonizes with eco-conscious driving.

Emissions Virtuosity: The marriage of enhanced power and fuel efficiency conducted by VVT translates into reduced emissions. By optimizing combustion, VVT minimizes unburned fuel and pollutants. It’s a virtuosity of emissions control, aligning with stringent environmental standards and contributing to cleaner air.

Smooth Transitions: VVT transitions seamlessly between different valve timing profiles. This means that drivers rarely notice the switch between low-end torque and high-end power; it all happens behind the scenes. The result is a remarkably smooth and uninterrupted acceleration experience.

Adaptive Precision: Modern VVT systems are adaptive, continuously fine-tuning valve timing based on sensor inputs like engine load, temperature, and throttle position. This adaptive precision ensures that the engine operates optimally under diverse driving conditions, from city traffic to highway cruising and even spirited driving on winding roads.

Sustainable Synergy: VVT is an integral component in the quest for more sustainable transportation. It aids in the optimization of engine efficiency, helping automakers meet stringent fuel economy and emissions regulations while delivering vehicles that are both powerful and eco-friendly.

In essence, Variable Valve Timing is the symphony conductor of the automotive world, orchestrating power, efficiency, and emissions control with remarkable precision. It exemplifies the marriage of performance and sustainability, offering a symphony of benefits that elevate the driving experience while contributing to a cleaner and more efficient future for the automotive industry.

For additional details, consider exploring the related content available here Variable Valve Actuation (VVA)

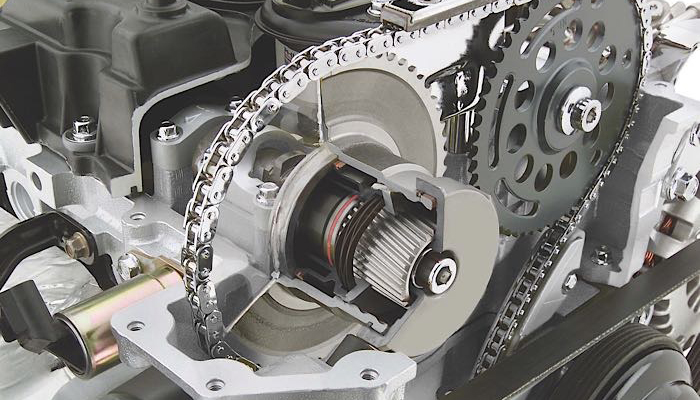

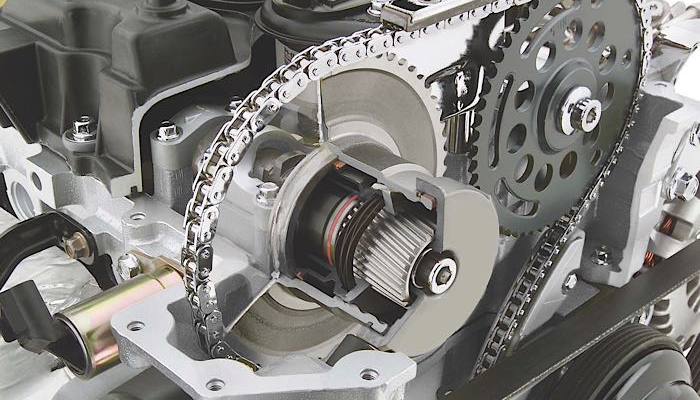

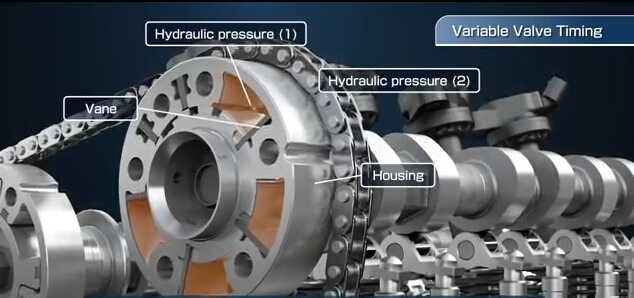

There are various types of VVT systems, including cam phasing, cam changing, and cam profile switching. Each system operates differently but shares the goal of optimizing valve timing.

Variability in Valve Timing (VVT) systems has brought about a spectrum of ingenious approaches, each designed to fine-tune an engine’s performance and efficiency in distinct ways. These VVT systems encompass a range of technologies, including cam phasing, cam changing, and cam profile switching, each with its unique operational characteristics and advantages. Let’s explore these systems in greater detail:

Cam Phasing:

- Continuous Adjustment: Cam phasing systems continuously alter the angular position of the camshaft relative to the crankshaft. This adjustment is typically achieved through a mechanism that can hydraulically or electronically change the camshaft’s orientation.

- Optimized Timing: The primary goal of cam phasing is to optimize valve timing in real-time, ensuring that the engine operates efficiently across different RPM ranges. This means adjusting the opening and closing of intake and exhaust valves for improved power delivery and fuel efficiency.

- Reduced Emissions: By precisely controlling valve timing, cam phasing contributes to reducing emissions and meeting stringent environmental standards.

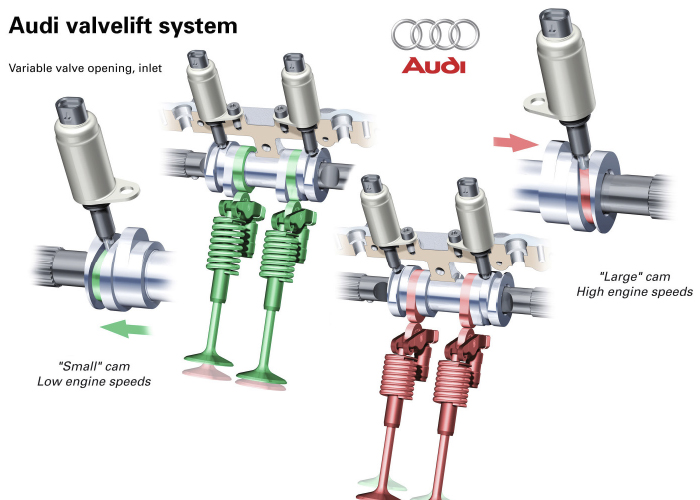

Cam Changing:

- Switchover Mechanism: Cam changing systems take a slightly different approach. They involve two sets of cam profiles with different valve timing events. A mechanism allows for the switchover between these cam profiles.

- Variable Performance: This technology provides two distinct performance profiles: one optimized for low-speed torque and the other for high-speed power. Drivers can benefit from enhanced performance across a broader RPM range.

- Efficiency and Versatility: Cam changing systems offer both efficiency gains during everyday driving and improved high-end power for dynamic acceleration.

Cam Profile Switching:

- Multiple Cam Profiles: Cam profile switching goes a step further by offering multiple cam profiles, each with specific valve timing characteristics. These profiles can be selected based on driving conditions and driver preferences.

- Dynamic Adaptability: This technology enables dynamic adaptability, allowing the engine to switch between profiles seamlessly during operation. It optimizes efficiency, power, and emissions control based on real-time requirements.

- Enhanced Performance: Cam profile switching is particularly advantageous in high-performance and sports applications, where rapid transitions between power and efficiency are desired.

In summary, the diverse world of VVT systems encompasses cam phasing, cam changing, and cam profile switching, each contributing to the overarching goal of optimizing valve timing. These systems are instrumental in enhancing engine efficiency, power delivery, and emissions control across a wide range of driving scenarios. They represent the continuous innovation and engineering ingenuity that drive the automotive industry forward, catering to the ever-evolving demands of drivers for performance, efficiency, and environmental responsibility.

For a comprehensive look at this subject, we invite you to read more on this dedicated page: Variable Valve Timing: What it is and Why Maintenance Is So …

By improving engine efficiency and reducing emissions, VVT technology aligns with global efforts to reduce the environmental footprint of internal combustion engines.

Variable Valve Timing (VVT) technology represents a pivotal advancement in the quest for more environmentally friendly and efficient internal combustion engines. Beyond the immediate benefits of enhanced engine efficiency and reduced emissions, VVT has far-reaching implications that align seamlessly with broader global environmental goals:

Optimized Combustion: VVT technology allows engines to adjust valve timing and lift according to driving conditions. This precision results in more complete and efficient combustion, minimizing unburned fuel and reducing harmful emissions such as nitrogen oxides (NOx) and carbon monoxide (CO). The reduction of these pollutants significantly improves air quality, contributing to better respiratory health and environmental well-being.

Fuel Economy Enhancement: Improved engine efficiency translates directly into better fuel economy. VVT-equipped engines can maximize power when needed, such as during acceleration, and operate with reduced power demands during cruising or idling. This dynamic optimization conserves fuel and reduces carbon dioxide (CO2) emissions, making VVT a valuable tool in the global effort to combat climate change.

Emission Compliance: Stricter emission standards worldwide necessitate innovative solutions like VVT to meet regulatory requirements. VVT technology enables engines to achieve compliance with increasingly stringent emission limits, reducing the automotive industry’s impact on air quality and the environment.

Noise Reduction: By fine-tuning valve timing, VVT technology contributes to quieter engine operation. Reduced noise pollution not only enhances the driving experience but also minimizes disruptions in urban and residential areas, fostering more peaceful and sustainable communities.

Extended Engine Lifespan: VVT can contribute to the longevity of engines by optimizing combustion and reducing wear and tear on engine components. A longer engine lifespan reduces the need for frequent replacements, conserving resources and reducing the environmental impact associated with manufacturing new engines.

Hybrid Powertrains: VVT plays a vital role in hybrid powertrains, where it complements electric propulsion by improving the efficiency of the internal combustion engine. This synergy results in lower overall fuel consumption and emissions in hybrid vehicles, offering a transitional solution as the world shifts toward electric mobility.

Research and Development: The development and refinement of VVT technology are driving broader research and development efforts within the automotive industry. This innovation mindset extends beyond VVT to other advanced engine technologies and alternative propulsion systems, accelerating the transition to cleaner and more sustainable transportation.

Consumer Adoption: As consumers become more environmentally conscious, VVT technology is a selling point for automakers. Vehicles equipped with VVT are perceived as eco-friendly and efficient, appealing to a growing market segment of environmentally aware consumers.

In conclusion, Variable Valve Timing (VVT) technology is a prime example of how engineering ingenuity can lead to significant advancements in engine efficiency and emissions reduction. Its widespread adoption in internal combustion engines aligns perfectly with global efforts to reduce the environmental footprint of vehicles, making it a critical component of the automotive industry’s journey toward sustainability and responsible resource management.

To expand your knowledge on this subject, make sure to read on at this location: Performance and power consumption optimization of a hydraulic …

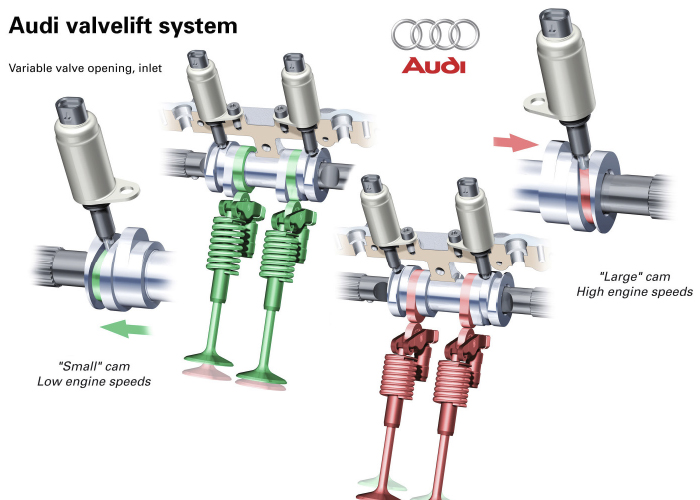

Variable Valve Lift, or VVL, is another technology that enhances engine performance and efficiency by allowing the engine to change the lift (height) of the intake and exhaust valves. This adjustment controls the amount of air entering the engine and is particularly beneficial during different driving conditions. Here’s how VVL works:

Variable Valve Lift, commonly known as VVL, stands as a testament to the intricate engineering that propels modern engines to new heights of performance and efficiency. It achieves this by offering a dynamic control over the lift or height of the intake and exhaust valves, adapting seamlessly to the ever-changing demands of driving conditions. Delving deeper into the inner workings of VVL, we unravel the remarkable technology:

Precision Valve Control: At the heart of VVL lies the capability to finely tune the lift of the intake and exhaust valves. This adjustment is not a one-size-fits-all approach but rather a precise orchestration that can vary valve lift across a spectrum, optimizing the engine’s performance and fuel efficiency for each specific situation.

Dynamic Response: VVL responds dynamically to different driving conditions. When you’re cruising along a highway, the system may reduce valve lift to enhance fuel economy by minimizing air resistance within the engine. Conversely, when you demand a burst of acceleration, the system swiftly adjusts to maximize valve lift, allowing a greater volume of air to enter the engine for added power.

Balancing Act: VVL is a masterful balancing act between power and efficiency. It maximizes power when you need it and conserves fuel when you don’t. This harmonious blend is especially evident in vehicles equipped with turbocharging or supercharging, where VVL complements forced induction systems to deliver a potent and efficient driving experience.

Fuel Savings: In urban stop-and-go traffic or during idling, VVL can reduce valve lift to optimize fuel savings. By limiting the air intake during low-load scenarios, the engine operates more efficiently, reducing fuel consumption and emissions. This not only benefits your wallet but also contributes to environmental sustainability.

Emissions Reduction: VVL plays a pivotal role in reducing emissions. By precisely controlling air intake and combustion, it helps engines meet stringent emissions standards. This is particularly important as environmental concerns continue to drive the development of cleaner and more eco-friendly vehicles.

Smooth Transition: The transition between different valve lift settings is seamless, thanks to sophisticated control algorithms and sensors that monitor various engine parameters. Drivers experience uninterrupted power delivery and performance, regardless of whether they are cruising on the highway or tackling challenging terrain.

Adaptability: VVL technology is adaptable and versatile, making it suitable for a wide range of engines, from small, efficient units in compact cars to high-performance powerplants in sports cars and SUVs. Its flexibility allows automakers to fine-tune engines to meet specific performance, efficiency, and emissions targets.

Future Potential: As automotive technology continues to evolve, so does the potential of VVL. Ongoing research and development aim to enhance its capabilities further, exploring innovations like variable valve timing (VVT) and cylinder deactivation for even greater efficiency and performance gains.

In conclusion, Variable Valve Lift, or VVL, represents a pivotal advancement in the realm of engine technology. Its ability to dynamically adjust valve lift to match driving conditions strikes a harmonious balance between power and efficiency, all while contributing to reduced emissions and fuel savings. As automotive engineering continues its relentless pursuit of excellence, VVL remains a cornerstone technology, ensuring that today’s vehicles are not only more powerful but also more environmentally responsible and responsive to the diverse demands of modern driving.

You can also read more about this here: ASM Gasoline Engine InCylinder

VVL systems alter the lift of the intake and exhaust valves based on engine speed, load, and driver demand. Lower lift settings are used for cruising and light load conditions, while higher lift settings are engaged for more demanding driving scenarios.

Variable Valve Lift (VVL) systems are a marvel of engineering ingenuity, delivering precision in power delivery by dynamically adjusting the lift of intake and exhaust valves in response to a multitude of factors.

Optimizing for Efficiency: In scenarios where cruising or light load conditions prevail, VVL seamlessly transitions to lower lift settings. This adjustment restricts the amount of air entering the combustion chambers, ensuring that the engine operates at its most fuel-efficient level. During highway cruising or city commuting, this not only conserves fuel but also reduces emissions, making it environmentally friendly.

On-Demand Performance: However, the true magic of VVL shines when the driver demands more power. As the throttle is opened wide or the engine speed climbs, VVL systems engage higher lift settings with precision. This allows a larger volume of air to enter the cylinders, promoting more thorough combustion and unleashing the engine’s full potential. Whether accelerating to merge onto a highway, overtaking slower traffic, or conquering steep inclines, VVL ensures that the engine delivers the requested power instantly and responsively.

Smooth Transition: The transition between different lift settings is seamless and imperceptible to the driver. Advanced control algorithms and sensors continuously monitor engine parameters, making split-second adjustments to maintain the ideal balance between power and efficiency. This level of precision ensures that the driving experience remains smooth and free of abrupt power surges or drops.

Reducing Noise and Vibration: VVL systems also contribute to a quieter and smoother ride. By optimizing valve lift, they help mitigate engine noise and vibration, enhancing passenger comfort during everyday driving and long-distance journeys.

Enhancing Engine Longevity: Operating an engine with variable valve lift allows manufacturers to design powerplants that achieve high performance when needed while remaining gentle on components during more relaxed driving conditions. This balance extends the longevity of the engine, reducing wear and tear and minimizing maintenance costs over time.

Adaptive Driving: VVL-equipped vehicles adapt to the driver’s style and road conditions. Whether you’re navigating a congested city street or enjoying a spirited drive on a winding country road, VVL ensures that the engine performs optimally, delivering power or efficiency as required.

Future Innovations: As technology continues to advance, we can expect even more sophisticated VVL systems. These may incorporate artificial intelligence and machine learning algorithms to predict driver behavior and road conditions, enabling proactive adjustments for an even more personalized and efficient driving experience.

In conclusion, Variable Valve Lift (VVL) is a technological masterpiece that brings a new level of precision and adaptability to internal combustion engines. It optimizes power delivery based on real-time factors such as engine speed, load, and driver demand, achieving a harmonious balance between performance and efficiency. VVL systems not only enhance the driving experience but also contribute to reduced fuel consumption and emissions, underscoring their pivotal role in the automotive industry’s journey toward a cleaner and more sustainable future.

Looking for more insights? You’ll find them right here in our extended coverage: Performance estimation of an engine with magnetorheological …

Balanced Performance: VVL ensures a balance between power and efficiency. Lower lift settings improve fuel efficiency during light load conditions, while higher lift settings enhance power output when needed.Reduced Emissions: Like VVT, VVL contributes to lower emissions by optimizing the combustion process and reducing fuel consumption.

Achieving a harmonious equilibrium between power and efficiency is at the core of what makes Variable Valve Lift (VVL) a game-changing technology in the automotive world. Let’s delve deeper into the multifaceted advantages of VVL, emphasizing its role in maintaining this delicate balance:

Balanced Performance Across the Spectrum:

VVL embodies the concept of dynamic adaptability, a trait that sets it apart in the pursuit of balanced engine performance. This technology excels at optimizing valve lift, effectively tailoring an engine’s characteristics to the driving conditions and driver’s demands. Here’s how VVL maintains equilibrium in engine performance:

Efficiency During Light Load Conditions: When the driving scenario calls for light throttle input, such as cruising on the highway or idling in traffic, VVL can lower the lift of the intake and exhaust valves. This adjustment minimizes the amount of air and fuel entering the combustion chamber, optimizing the engine for fuel efficiency. By reducing power output during such conditions, VVL ensures that the engine operates in a highly economical state, consuming only the necessary resources.

Power Surge When Needed: Conversely, when the driver requests more power—perhaps during acceleration or overtaking—VVL springs into action to maximize valve lift. This adjustment allows a larger volume of air and fuel to enter the combustion chamber, boosting power output significantly. By seamlessly transitioning to higher valve lift settings, VVL ensures that the engine delivers the needed punch, all while maintaining efficiency during gentler driving.

Seamless Transitions: One of VVL’s remarkable qualities is its ability to execute these transitions between low and high lift settings seamlessly. The switch is often imperceptible to the driver, providing a smooth and uninterrupted driving experience. This dynamic control ensures that power delivery is on demand without any noticeable lag or hesitation.

Reduced Emissions and Environmental Responsibility:

In an era where environmental concerns are paramount, VVL stands as a stalwart ally in the fight against emissions. It complements the efforts of Variable Valve Timing (VVT) by further optimizing the combustion process and reducing fuel consumption, resulting in a virtuous cycle of benefits:

Precise Combustion Control: VVL’s ability to fine-tune valve lift contributes to precise control over the air-fuel mixture entering the engine. This precision enhances the efficiency of the combustion process, ensuring that the fuel is consumed more completely and producing fewer unburned hydrocarbons. Reduced emissions are particularly critical in meeting strict emissions standards worldwide.

Economical Driving: By optimizing valve lift and timing, VVL helps vehicles operate in a more economical mode during everyday driving conditions. This translates into reduced fuel consumption and fewer greenhouse gas emissions, aligning with environmental regulations and consumer expectations for eco-friendly vehicles.

Hybrid Synergy: In hybrid powertrains, VVL complements electric propulsion by fine-tuning the combustion engine’s efficiency. The ability to switch between low and high lift settings seamlessly allows hybrid vehicles to extract maximum efficiency during both electric and gasoline-powered operation, resulting in reduced emissions and greater fuel savings.

Future-Proofing: As the automotive industry transitions toward electrification and alternative power sources, VVL continues to play a pivotal role. By optimizing the efficiency of internal combustion engines, it contributes to extending the useful life of these powertrains while automakers explore and develop alternative propulsion technologies.

In summary, Variable Valve Lift (VVL) embodies the pursuit of balance in engine performance, offering the best of both worlds: efficiency during light load conditions and power surges when needed. Its seamless transitions and dynamic adaptability enrich the driving experience while reducing emissions and fuel consumption. As automotive technology evolves to meet the challenges of the future, VVL remains an invaluable tool in the industry’s commitment to sustainable, efficient, and responsive powertrains.

If you’d like to dive deeper into this subject, there’s more to discover on this page: VARIABLE VALVE TIMING

VVL systems can vary in complexity, with some using discrete steps of lift adjustment, while others offer continuous lift control. More advanced systems can switch between different cam profiles to achieve the desired lift.

Variable Valve Lift (VVL) systems, a sibling technology to Variable Valve Timing (VVT), add yet another layer of sophistication to modern engines, further fine-tuning their performance and efficiency. These systems introduce the capability to alter the actual lift of the engine’s intake and exhaust valves, providing a nuanced approach to optimizing engine operation.

Discrete vs. Continuous Lift Control: VVL systems come in various flavors, each offering a different level of control over valve lift. Some employ discrete steps of lift adjustment, which means that they can switch between predefined lift settings. This discrete approach is effective in delivering distinct performance characteristics, such as enhancing low-end torque for everyday driving or maximizing high-end power for spirited acceleration.

Continuous Lift Adjustment: More advanced VVL systems, on the other hand, offer continuous lift control. This means that they can finely adjust the valve lift to any point within a predefined range, rather than being confined to preset steps. Continuous lift adjustment is a bit like having an infinitely adjustable valve system, allowing the engine management system to precisely tailor valve lift based on real-time operating conditions.

Cam Profile Switching: At the heart of VVL systems lies the ability to switch between different cam profiles. Cam profiles dictate the valve lift and duration. Advanced VVL systems feature multiple cam profiles that can be engaged as needed. For instance, when driving at low speeds or cruising on the highway, a profile optimized for fuel efficiency may be engaged. In contrast, during aggressive acceleration or high-performance driving, a profile designed for maximum power output can be activated. This dynamic switching ensures that the engine operates optimally across a wide range of conditions.

Balancing Power and Efficiency: VVL technology is a powerful tool for striking a balance between power and efficiency. During typical driving scenarios, engines can operate in a fuel-efficient mode, conserving energy. However, when the driver demands more power, such as for overtaking or merging onto a highway, the system seamlessly transitions to a high-lift profile, delivering the necessary power while still maintaining an efficient overall operation.

Environmental Benefits: The adaptability of VVL systems extends to environmental benefits. By optimizing valve lift and timing, these systems contribute to improved fuel efficiency, reduced emissions, and overall cleaner combustion. This makes them an integral component in the pursuit of eco-friendly and sustainable automotive solutions.

Adoption and Evolution: VVL systems are becoming increasingly common across a range of vehicles, from economy cars to high-performance sports cars. As technology advances, we can expect even more sophisticated and finely tuned VVL systems that further push the boundaries of engine efficiency and performance.

In conclusion, Variable Valve Lift (VVL) systems represent a pinnacle of precision in engine control. Their ability to adjust valve lift continuously or switch between different cam profiles allows engines to optimize performance, efficiency, and emissions across a wide spectrum of driving conditions. As these systems continue to evolve, they hold the promise of even greater advancements in the realms of power, efficiency, and environmental responsibility, shaping the future of automotive engineering.

Don’t stop here; you can continue your exploration by following this link for more details: Effects of Variable Intake Valve Timings and Valve Lift on the …

VVT and VVL technologies have had a profound impact on the automotive industry. They enable automakers to develop engines that offer a winning combination of power, efficiency, and reduced emissions. Here are some key takeaways regarding their influence:

VVT (Variable Valve Timing) and VVL (Variable Valve Lift) technologies have indeed had a profound impact on the automotive industry, reshaping the way engines operate and delivering a winning combination of power, efficiency, and reduced emissions. Let’s delve deeper into the key takeaways regarding their influence:

Balancing Power and Efficiency: VVT and VVL technologies allow automakers to strike a delicate balance between power and efficiency. Engines equipped with these systems can deliver ample power when needed, such as during acceleration or overtaking, while seamlessly transitioning to a more fuel-efficient mode during cruising. This versatility caters to a broad spectrum of driving scenarios.

Emissions Reduction: The fine-tuned control of valve timing and lift achieved through VVT and VVL systems contributes significantly to emissions reduction. By optimizing the combustion process, these technologies minimize the release of pollutants and greenhouse gases, aligning with strict emissions standards and environmental objectives.

Enhanced Fuel Economy: VVT and VVL systems improve fuel economy by ensuring that the engine operates at its most efficient levels across various RPM ranges. This translates to fewer trips to the gas pump, saving consumers money and reducing the overall carbon footprint associated with driving.

Performance Enhancement: Automotive enthusiasts benefit from VVT and VVL as these technologies enhance engine performance. Whether in sports cars, high-performance sedans, or even off-road vehicles, the ability to vary valve timing and lift results in more responsive and powerful engines, providing an exhilarating driving experience.

Adaptability to Diverse Engines: VVT and VVL are adaptable technologies applicable to a wide range of engines, including four-cylinder, six-cylinder, and even high-performance V8 engines. Automakers can implement these systems across their vehicle lineups, from economy cars to luxury vehicles, to achieve a balance between performance and efficiency that suits different market segments.

Cold Start Efficiency: During cold starts, when engines are less efficient and emissions are typically higher, VVT and VVL systems play a crucial role. They can keep the valves open longer to expedite engine warm-up, reducing emissions and enhancing the longevity of engine components.

Integration with Hybrid Technology: VVT and VVL technologies can be integrated into hybrid powertrains to further optimize efficiency and performance. In hybrid vehicles, these systems work in concert with electric motors, allowing for seamless transitions between gasoline and electric power, enhancing overall fuel efficiency.

Continual Innovation: As automotive technology advances, so do VVT and VVL systems. Engineers are continually refining these technologies, incorporating more sophisticated control algorithms and materials to further enhance performance and efficiency.

Regulatory Compliance: Stricter emissions regulations and fuel efficiency standards are driving the widespread adoption of VVT and VVL systems. Automakers are leveraging these technologies to meet regulatory requirements and demonstrate their commitment to environmental responsibility.

In conclusion, VVT and VVL technologies represent a pivotal chapter in the automotive industry’s ongoing evolution. They embody the industry’s commitment to delivering vehicles that are not only powerful and efficient but also environmentally responsible. As automotive engineering continues to push boundaries, these technologies will remain essential in shaping the vehicles of the future, offering consumers an ever-improving combination of performance and sustainability.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Variable Valve Timing: What it is and Why Maintenance Is So …

VVT and VVL technologies have facilitated engine downsizing. Smaller engines with forced induction (turbocharging or supercharging) and advanced valve control systems can deliver the power of larger engines while consuming less fuel.

The advent of Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies has ushered in a transformative era in engine design, enabling a paradigm shift known as engine downsizing. This strategic downsizing is a testament to the ingenuity of engineers and the potential of cutting-edge technologies to redefine automotive performance and efficiency:

Optimized Displacement: Engine downsizing entails reducing the cubic displacement of an engine while maintaining or even improving its performance. VVT and VVL technologies play a pivotal role in this process by ensuring that the engine operates at its most efficient and potent state across a wide range of operating conditions. As a result, smaller engines can punch above their weight class, delivering power levels that were once the domain of larger, thirstier powerplants.

Forced Induction Synergy: Downsized engines often embrace the symbiosis of VVT/VVL with forced induction systems like turbocharging or supercharging. These systems provide a breath of fresh air (literally) to smaller engines, boosting their power output by compressing incoming air. VVT and VVL technologies complement this forced induction, ensuring that the engine’s valvetrain synchronizes harmoniously with the additional airflow. This synergy results in impressive power gains without compromising efficiency.

Eco-Friendly Efficiency: Smaller, downsized engines with VVT and VVL can strike a harmonious balance between performance and fuel efficiency. The ability to adapt valve timing and lift to varying driving conditions means that these engines can sip fuel during leisurely cruising and deliver spirited acceleration when needed. This duality aligns with modern drivers’ expectations for both efficiency and dynamic performance.

Reduced Emissions: Downsizing engines with VVT and VVL also contributes to reducing emissions. The precise control of valve timing and lift enables engines to operate closer to their optimal efficiency points, minimizing the release of harmful pollutants. This is a significant step in addressing environmental concerns while maintaining vehicle performance.

Enhanced Responsiveness: Downsized engines equipped with VVT and VVL exhibit remarkable responsiveness. They can deliver instant torque, thanks to the optimized valve control systems, making them adept at quick accelerations and confident overtaking maneuvers. This responsiveness enhances the overall driving experience, especially in urban traffic and on winding roads.

Weight Reduction: Smaller engines not only occupy less space under the hood but also contribute to overall vehicle weight reduction. This weight savings can further enhance fuel efficiency and handling characteristics, culminating in a well-rounded driving experience.

Future-Ready: Downsizing, backed by advanced valve control technologies, positions automakers for the future. As environmental regulations continue to evolve, and electric powertrains gain traction, downsized engines can serve as efficient and eco-friendly power sources for hybrid and plug-in hybrid vehicles. This adaptability ensures that these engines remain relevant and sustainable in the ever-changing automotive landscape.

In the realm of engine downsizing, the integration of VVT and VVL technologies is nothing short of revolutionary. It empowers automakers to deliver smaller, more efficient, and environmentally conscious powerplants without sacrificing the exhilaration of driving. This transformative approach is not merely about reducing engine size; it’s about maximizing the potential of every drop of fuel and redefining the boundaries of automotive performance and efficiency.

Don’t stop here; you can continue your exploration by following this link for more details: Naturally aspirated gasoline engines and cylinder deactivation

Stricter emissions regulations worldwide have made VVT and VVL technologies essential for automakers to meet environmental standards while providing powerful and fuel-efficient vehicles.

The ever-tightening grip of emissions regulations around the globe has spurred a transformative shift in the automotive industry. Varied and rigorous standards mandate lower emissions of greenhouse gases and pollutants, pushing automakers to adopt innovative technologies like Variable Valve Timing (VVT) and Variable Valve Lift (VVL). These technologies are now indispensable tools for automakers striving to not only meet stringent environmental standards but also deliver vehicles that strike the delicate balance between power, fuel efficiency, and reduced emissions.

Environmental Imperatives: The urgency to combat climate change and reduce air pollution has driven governments worldwide to impose stricter emissions limits. VVT and VVL technologies directly address these concerns by optimizing engine combustion and reducing harmful emissions, particularly nitrogen oxides (NOx) and carbon dioxide (CO2).

Fuel Efficiency Enhancement: VVT and VVL systems significantly contribute to fuel efficiency improvements. By dynamically adjusting valve timing and lift according to engine load and speed, these technologies enable engines to operate at their most efficient points. This translates to reduced fuel consumption, lower operating costs for consumers, and reduced reliance on fossil fuels.

Power without Compromise: VVT and VVL technologies have revolutionized the concept of power and efficiency coexisting. Modern engines equipped with these systems can deliver impressive power outputs while maintaining compliance with emissions regulations. Drivers can enjoy spirited acceleration and dynamic performance without harming the environment.

Downsizing and Downspeeding: Automakers are increasingly downsizing engines, thanks to the benefits offered by VVT and VVL. Smaller-displacement engines equipped with forced-induction and advanced valve control can deliver the power and torque of larger engines while consuming less fuel. Downsizing reduces the carbon footprint and promotes resource efficiency.

Hybrid Synergy: VVT and VVL technologies are often integrated into hybrid powertrains, further optimizing their efficiency and emissions performance. These systems enhance the overall efficiency of hybrid engines by managing the combustion process more precisely, complementing the electric power component.

Global Compliance: As emissions regulations become more uniform across the world, automakers must engineer vehicles that can meet these standards in diverse markets. VVT and VVL technologies offer a versatile solution, allowing automakers to design engines that can adapt to various emissions requirements while maintaining performance.

Technological Evolution: Ongoing research and development efforts continue to refine VVT and VVL systems. Innovations like electrically actuated valvetrains and advanced control algorithms promise even greater efficiency and emissions reductions.

Consumer Demand: Consumer preferences are increasingly aligned with environmental consciousness. Buyers are seeking vehicles that not only meet regulatory standards but also reflect their commitment to sustainability. VVT and VVL technologies empower automakers to offer eco-friendly options without compromising on performance.

Competitive Advantage: Automakers that lead the way in implementing and optimizing VVT and VVL technologies gain a competitive edge. These technologies signify a commitment to environmental stewardship and resonate with eco-conscious consumers.

In conclusion, the landscape of the automotive industry has been forever altered by the imperative of reducing emissions and enhancing fuel efficiency. VVT and VVL technologies have emerged as indispensable tools that enable automakers to navigate this new terrain successfully. They embody the industry’s commitment to responsible innovation, ensuring that powerful, fuel-efficient, and environmentally friendly vehicles remain within reach for today’s and future generations of drivers.

Don’t stop here; you can continue your exploration by following this link for more details: Improving Thermal Efficiency of Internal Combustion Engines …

VVT and VVL systems have found applications in hybrid and electric powertrains, where they optimize the efficiency of internal combustion engines used in conjunction with electric motors.

The integration of Variable Valve Timing (VVT) and Variable Valve Lift (VVL) systems into hybrid and electric powertrains is a testament to their adaptability and importance in optimizing the overall efficiency of advanced propulsion systems. Beyond their traditional applications in internal combustion engines, these technologies play a crucial role in enhancing the performance and sustainability of hybrid and electric vehicles:

Efficient Energy Management: Hybrid powertrains combine internal combustion engines with electric motors to achieve a balance between performance and efficiency. VVT and VVL systems help extract maximum efficiency from the combustion engine, ensuring that it operates within its optimal power band. This synergy with electric propulsion maximizes overall energy utilization and extends the electric-only driving range.

Seamless Transitions: The integration of VVT and VVL allows for smoother transitions between the internal combustion engine and electric motor operation. By precisely controlling valve timing and lift, these systems ensure a seamless handover of power sources, minimizing driveline vibrations and delivering a more refined driving experience.

Regenerative Braking Optimization: During regenerative braking, where kinetic energy is converted into electrical energy to recharge the battery, VVT and VVL systems play a role in adjusting engine parameters. This fine-tuning optimizes energy recovery, ensuring that as much kinetic energy as possible is harnessed and stored for later use.

Start-Stop Functionality: VVT and VVL systems enhance the efficiency of start-stop systems commonly found in hybrid vehicles. When the engine restarts after coming to a stop, these systems help ensure that it operates in the most fuel-efficient manner, reducing emissions and fuel consumption during idling and low-load conditions.

Eco-Friendly Operation: In plug-in hybrid electric vehicles (PHEVs), VVT and VVL technology contributes to eco-friendly operation. These systems work in harmony with electric-only propulsion to minimize emissions during hybrid mode, making PHEVs an attractive option for environmentally conscious drivers.

Extended Electric-Only Range: By optimizing the efficiency of the internal combustion engine, VVT and VVL technology helps extend the electric-only driving range of hybrid vehicles. This extension reduces the overall reliance on fossil fuels, contributing to lower carbon emissions and enhanced sustainability.

Regulatory Compliance: Stricter emissions standards and efficiency regulations have accelerated the adoption of VVT and VVL systems in hybrid and electric powertrains. These technologies enable automakers to meet stringent environmental requirements while providing customers with more fuel-efficient and eco-friendly vehicles.

Hybrid Vehicle Diversity: VVT and VVL are not limited to a specific type of hybrid system. They are versatile technologies that find applications in various hybrid architectures, including mild hybrids, full hybrids, and plug-in hybrids. Their adaptability ensures that different hybrid models can benefit from improved efficiency and reduced emissions.

In summary, the incorporation of VVT and VVL systems into hybrid and electric powertrains underscores their pivotal role in advancing the efficiency and eco-friendliness of modern vehicles. These technologies contribute to a seamless and efficient synergy between internal combustion engines and electric motors, resulting in more sustainable transportation solutions that align with the evolving landscape of automotive technology and environmental responsibility.

Additionally, you can find further information on this topic by visiting this page: Improving Thermal Efficiency of Internal Combustion Engines …

These technologies have improved the driving experience by ensuring that engines are responsive across a wide range of operating conditions, from city commuting to highway cruising.

Indeed, the integration of advanced technologies, such as Variable Valve Lift (VVL) and Variable Valve Timing (VVT), has ushered in a new era of automotive engineering, significantly enhancing the driving experience. These innovations are engineered to ensure that engines remain responsive and adaptable, delivering optimal performance and efficiency across a diverse spectrum of driving conditions, from navigating congested city streets to cruising effortlessly on expansive highways. Here’s how these technologies continue to shape and elevate the driving experience:

Urban Agility: In the hustle and bustle of city commuting, VVL and VVT work in unison to provide the ideal balance of power and efficiency. VVT adjusts the timing of the engine’s intake and exhaust valves, optimizing torque delivery at lower RPMs, making stop-and-go traffic more manageable, and enhancing fuel efficiency.

Highway Prowess: On the open road, when you crave exhilarating acceleration for overtaking or merging with fast-moving traffic, these technologies shine. VVL steps in to maximize valve lift, allowing a surge of air into the engine, resulting in immediate and robust power delivery. The precise timing adjustments of VVT further fine-tune performance, ensuring the engine remains in its powerband for effortless highway cruising.

Economical Efficiency: Beyond the urban jungle and highway stretches, these technologies continue to excel. During steady-state cruising, VVL and VVT combine forces to optimize fuel efficiency. By adjusting valve lift and timing, they maintain a delicate equilibrium between power and frugality, making long-distance journeys more economical and reducing your carbon footprint.

Versatility for All Vehicles: VVL and VVT are versatile technologies that cater to a broad spectrum of vehicles. They can be found in compact cars, SUVs, trucks, and high-performance sports cars. This versatility ensures that no matter the vehicle type, you can expect a responsive and efficient engine that adapts to your driving needs.

Adaptive Engineering: Automotive engineers continually refine these technologies, leveraging advanced control systems, sensors, and software algorithms. This adaptive engineering ensures that the transition between different valve lift and timing settings is seamless, guaranteeing a smooth and uninterrupted driving experience.

Meeting Emissions Standards: As emissions standards become increasingly stringent, VVL and VVT play a pivotal role in helping engines meet these regulatory requirements. Their precise control over combustion processes contributes to reduced emissions and a greener driving experience.

Enhanced Reliability: These technologies also contribute to engine durability and reliability. By optimizing valve lift and timing, they reduce stress on engine components, minimize wear and tear, and extend the overall lifespan of the powerplant.

Tuned for Performance: In high-performance vehicles, VVL and VVT are fine-tuned to deliver exhilarating acceleration and handling. This means that enthusiasts can enjoy a thrilling driving experience on winding roads and racetracks, with engines that respond to the slightest touch of the accelerator pedal.

In essence, Variable Valve Lift and Variable Valve Timing have evolved into indispensable components of the modern driving experience. Their ability to adapt to various driving scenarios, optimize performance and efficiency, and align with environmental goals ensures that today’s engines are not only responsive but also eco-conscious. As these technologies continue to evolve and become more sophisticated, they will undoubtedly play an even more prominent role in shaping the future of automotive performance and sustainability.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Variable Valve Timing: What it is and Why Maintenance Is So …

Conclusion

Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies exemplify the automotive industry’s commitment to balancing power and efficiency while reducing environmental impact. They have become integral components in modern engines, enabling vehicles to deliver the performance consumers desire without compromising fuel economy or emissions. As automotive technology continues to evolve, VVT and VVL systems will play an increasingly significant role in shaping the future of internal combustion engines and hybrid powertrains, offering precise control and improved efficiency for the vehicles of tomorrow.

Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies represent a pivotal step forward in the automotive industry’s relentless pursuit of optimizing every facet of engine performance. These technologies, rather than representing incremental improvements, are transformative forces that have reshaped the very core of engine design and operation.

Evolving Engine Efficiency: VVT and VVL are at the forefront of the automotive industry’s commitment to achieving greater engine efficiency. While conventional engines remain a dominant force on the road, VVT and VVL are pushing the boundaries of what is possible. By continuously refining the timing and lift of valves, these technologies enable engines to extract more power from each drop of fuel while minimizing waste and emissions.

A Green Revolution: In an era when environmental concerns are paramount, VVT and VVL are shining examples of how the automotive industry is making a concerted effort to reduce its carbon footprint. By enhancing combustion efficiency, these technologies reduce the amount of greenhouse gases produced per unit of power generated. This not only aligns with emissions standards but also demonstrates a commitment to a cleaner and more sustainable future.

Fuel Economy without Compromise: One of the remarkable features of VVT and VVL is their ability to deliver improved fuel economy without compromising performance. In the past, consumers often faced a trade-off between power and efficiency. With VVT and VVL, automakers have transcended this limitation, offering vehicles that are not only powerful but also frugal when it comes to fuel consumption.

Pioneering Hybrid Powertrains: As the automotive industry evolves, the line between traditional internal combustion engines and hybrid powertrains is blurring. VVT and VVL are essential components in these hybrid systems, helping internal combustion engines work in harmony with electric propulsion. This integration further enhances efficiency and reduces emissions, setting the stage for a future where hybrid vehicles are the norm.

An Ongoing Revolution: VVT and VVL are not static technologies; they are part of an ongoing revolution. Engineers and researchers are continually exploring ways to improve these systems, making them even more precise and responsive. Future innovations may include adaptive algorithms that can anticipate driving scenarios, providing an even more tailored and efficient engine performance.

Accessibility and Adoption: As VVT and VVL technologies become more refined and cost-effective, they are finding their way into a wider range of vehicles, from high-performance sports cars to compact commuter cars. This democratization of advanced engine technology means that more consumers can benefit from improved efficiency and power without breaking the bank.

In closing, Variable Valve Timing (VVT) and Variable Valve Lift (VVL) are not just technologies; they are the embodiment of a commitment to engineering excellence and environmental stewardship. They have revolutionized how we view internal combustion engines, making them more powerful, efficient, and environmentally friendly. As these technologies continue to evolve and proliferate, they will remain at the heart of the automotive industry’s efforts to shape a more sustainable and exciting future of transportation.

Explore this link for a more extensive examination of the topic: Performance estimation of an engine with magnetorheological …

More links

You can also read more about this here: Performance and power consumption optimization of a hydraulic …