Introduction

The automotive industry is in a constant state of evolution, driven by advancements in technology, stringent safety regulations, and the growing demand for more efficient and environmentally friendly vehicles. At the heart of this transformation lies the crucial process of vehicle testing and simulation. These methods have become indispensable tools for automakers and engineers, allowing them to fine-tune every aspect of a vehicle’s performance, safety, and efficiency. In this article, we will delve into the world of vehicle testing and simulation methods, exploring their significance, the various types of tests employed, and the pivotal role they play in shaping the cars we drive today.

Explore this link for a more extensive examination of the topic: Optimizing vehicle dynamics co-simulation performance by …

Safety is a paramount concern in the automotive industry, and vehicle testing plays a pivotal role in ensuring that vehicles meet or exceed safety standards. Crash tests, for example, simulate real-world collisions to evaluate a vehicle’s structural integrity and occupant protection. Advanced simulations allow engineers to identify potential safety issues and make design improvements before physical prototypes are built.

Safety is unequivocally the bedrock of the automotive industry, guiding every facet of vehicle design and engineering. Vehicle testing, in particular, stands as an indispensable pillar in the relentless pursuit of utmost safety, offering insights and assurance through meticulous evaluations. Here’s an exploration of how testing unfolds to ensure that vehicles not only meet but surpass safety standards:

Comprehensive Testing Regimens: Vehicle safety is not a single-point endeavor but a rigorous and all-encompassing process. It encompasses a battery of tests that scrutinize every conceivable scenario, from crashworthiness to rollover resistance, and even pedestrian safety. These multifaceted evaluations leave no stone unturned in the quest for safety perfection.

Crash Testing Excellence: Among the most well-known safety tests are crash tests, which simulate real-world collisions with painstaking accuracy. By subjecting vehicles to controlled crashes, engineers assess their structural integrity and the effectiveness of safety systems. These tests provide invaluable insights into how a vehicle performs in life-threatening situations, ensuring that occupants are shielded from harm.

Occupant Protection: Ensuring the well-being of vehicle occupants is paramount. Testing evaluates airbag deployment, seatbelt effectiveness, and the ability of the vehicle’s structure to absorb and dissipate energy during a crash. Realistic crash dummies equipped with sensors collect data to gauge the likelihood of injury, informing refinements in safety design.

Advanced Simulations: Modern technology has ushered in a new era of vehicle safety through advanced simulations. Engineers use sophisticated software to model and predict the behavior of vehicles under various conditions. These simulations are instrumental in identifying potential safety issues and making critical design improvements before physical prototypes are constructed.

Pedestrian Safety: Vehicle safety extends beyond the cabin to protect vulnerable road users. Testing now includes assessments of pedestrian safety, evaluating how vehicles mitigate harm in collisions with pedestrians, cyclists, and other non-occupants.

Electronic Safety Systems: In addition to passive safety measures, electronic safety systems like adaptive cruise control, lane-keeping assist, and automatic emergency braking are thoroughly tested. These technologies are designed to prevent accidents and enhance driver safety.

Autonomous Vehicle Safety: As autonomous vehicles emerge, a new dimension of safety testing arises. Ensuring the reliability and safety of autonomous systems involves extensive testing in simulated and real-world scenarios, with a strong focus on their ability to make split-second decisions to avoid accidents.

Regulatory Compliance: Vehicle manufacturers must adhere to a web of stringent safety regulations and standards enforced by governmental agencies. These regulations evolve to keep pace with emerging technologies and changing safety expectations.

Data-Driven Improvements: Testing generates a wealth of data that is meticulously analyzed. This data-driven approach enables continuous improvement in vehicle safety, leading to the development of safer designs and more effective safety systems.

In conclusion, safety remains at the core of automotive innovation, and rigorous testing is the crucible in which safety solutions are forged. The automotive industry’s unwavering commitment to enhancing vehicle safety continues to save lives, reduce injuries, and pave the way for a future where accidents on our roads are a rare occurrence.

To expand your knowledge on this subject, make sure to read on at this location: Driving to Safety: How Many Miles of Driving Would It Take to …

Vehicle performance encompasses aspects such as acceleration, handling, braking, and fuel efficiency. Testing and simulation methods enable engineers to analyze and fine-tune these parameters. High-performance vehicles undergo rigorous testing on race tracks and in wind tunnels, allowing engineers to optimize aerodynamics, suspension, and powertrain components.

The pursuit of exceptional vehicle performance is a multifaceted endeavor that extends far beyond the parameters mentioned. Engineers are continually pushing the boundaries to enhance every aspect of a vehicle’s performance, creating cars that deliver unparalleled experiences on the road:

Cornering and Handling Precision: In addition to straight-line acceleration, high-performance vehicles are engineered for sharp cornering and precise handling. Suspension systems are meticulously tuned, and advanced technologies like active suspension and adaptive dampers are employed to maintain optimal tire contact with the road, ensuring stability and control even in tight turns.

Braking Dynamics: Braking performance is another critical aspect of vehicle performance. High-performance vehicles are equipped with powerful braking systems, often featuring larger and ventilated disc brakes, advanced brake calipers, and high-friction brake pads. Engineers work to optimize brake balance and heat dissipation for consistent and reliable stopping power.

Weight Distribution: Achieving the ideal weight distribution across the vehicle is crucial for balanced handling. Engineers carefully distribute the weight of the engine, transmission, and other components to ensure optimal handling characteristics and prevent understeer or oversteer during cornering.

Tire Technology: Tires are a vital link between the vehicle and the road. High-performance vehicles often come equipped with specialized, high-grip tires designed for precise steering response and maximum traction. Tire technology is a focal point for enhancing both handling and acceleration.

Advanced Materials: The use of lightweight materials, such as carbon fiber, aluminum, and magnesium, helps reduce the overall weight of high-performance vehicles. This weight reduction not only improves acceleration and handling but also contributes to better fuel efficiency.

Aerodynamics Refinement: Aerodynamic optimization goes beyond just wind resistance reduction. Engineers use wind tunnels and computational simulations to fine-tune aerodynamic features, including spoilers, diffusers, and even active aerodynamic elements that can adjust in real-time to enhance downforce or reduce drag.

Powertrain Enhancements: High-performance vehicles often feature powerful engines, sometimes equipped with turbochargers or superchargers, to deliver exceptional acceleration. Tuning the engine’s power delivery and torque curve is an intricate process that requires extensive testing and refinement.

Exhaust System Tuning: The exhaust system isn’t just for expelling gases; it plays a role in engine performance and sound. Engineers optimize the exhaust system to improve power output while creating an appealing and distinctive exhaust note.

Driver Assistance Systems: High-performance vehicles may incorporate advanced driver assistance systems (ADAS) to enhance safety and control. These systems, such as adaptive cruise control, lane-keeping assist, and traction control, work in harmony with performance components to provide a safe and exhilarating driving experience.

Environmental Considerations: As the automotive industry embraces sustainability, high-performance vehicles are evolving to be more environmentally conscious. Some are incorporating hybrid or electric powertrains to deliver electrifying acceleration with reduced emissions.

Customization Options: Many high-performance vehicles offer customization options, allowing owners to tailor their cars to their specific preferences. This includes selecting driving modes that adjust suspension settings, engine response, and other parameters to suit different driving scenarios.

In conclusion, the pursuit of vehicle performance excellence is a dynamic and multifaceted journey. Engineers employ cutting-edge technologies, conduct exhaustive testing, and continuously refine designs to create high-performance vehicles that excel in acceleration, handling, braking, and fuel efficiency. These vehicles are a testament to the relentless commitment to pushing the limits of automotive engineering, delivering thrilling driving experiences for enthusiasts while also addressing evolving environmental and safety considerations.

You can also read more about this here: Optimizing vehicle dynamics co-simulation performance by …

As environmental concerns grow, automakers are under increasing pressure to reduce emissions. Emission testing and simulation methods help ensure compliance with strict environmental regulations. This includes testing exhaust emissions, improving engine efficiency, and developing hybrid and electric vehicle technologies.

The escalating urgency of environmental concerns has catalyzed a profound transformation within the automotive industry. Beyond reducing emissions, automakers are embracing a comprehensive approach to sustainability and environmental responsibility:

Alternative Propulsion Systems: Alongside improving engine efficiency, automakers are investing heavily in alternative propulsion systems. Hybrid and electric vehicle technologies are at the forefront of this shift. The development of electric powertrains, advanced battery technologies, and infrastructure for electric vehicle charging reflects a commitment to reducing not only tailpipe emissions but also the overall carbon footprint of the automotive sector.

Emission Reduction Beyond Tailpipe: While tailpipe emissions are a focal point, automakers are increasingly addressing emissions throughout a vehicle’s lifecycle. This includes efforts to reduce emissions generated during the manufacturing process and emissions associated with vehicle disposal at the end of its life. Sustainable materials, recycling initiatives, and circular economy principles are being integrated into automotive manufacturing.

Lightweighting and Efficiency: Improving engine efficiency is just one aspect of enhancing vehicle efficiency. Lightweighting, the use of advanced materials, and aerodynamic design all play a role in reducing fuel consumption and emissions. These measures not only align with environmental goals but also improve overall vehicle performance.

Advanced Materials: Automakers are exploring innovative materials with lower environmental footprints. These materials may be sourced sustainably, require fewer resources to produce, or have superior recycling capabilities. They contribute to both emissions reduction and the responsible use of resources.

Connected and Autonomous Vehicles: The rise of connected and autonomous vehicles offers opportunities for emission reduction through smarter transportation systems. These vehicles can optimize routes, reduce congestion, and facilitate carpooling, all of which contribute to lower emissions in urban environments.

Renewable Energy Integration: Beyond vehicle technology, automakers are exploring partnerships with renewable energy providers to power their manufacturing facilities and charging infrastructure with clean energy. This approach ensures that the entire ecosystem surrounding vehicles operates in an environmentally responsible manner.

Consumer Education: Automakers are actively engaging consumers in understanding the environmental impact of their vehicles. Many provide information on fuel efficiency, emissions ratings, and the benefits of hybrid and electric options. Informed consumers are more likely to make eco-conscious choices.

Regulatory Compliance: Compliance with strict environmental regulations remains a top priority. Automakers continue to invest in emission testing and simulation methods to ensure they meet or exceed regulatory requirements, avoiding penalties and demonstrating commitment to environmental stewardship.

In conclusion, the automotive industry’s response to environmental concerns extends far beyond emission reduction. It encompasses a holistic transformation that integrates sustainability throughout the entire vehicle lifecycle and embraces alternative technologies, advanced materials, and eco-conscious consumer education. As the industry continues to evolve, these efforts will play a pivotal role in shaping a more sustainable and responsible future for mobility.

To expand your knowledge on this subject, make sure to read on at this location: Impacts of Autonomous Vehicles on Greenhouse Gas Emissions …

Vehicles must withstand the rigors of daily use, from pothole-ridden roads to extreme weather conditions. Durability testing simulates years of wear and tear, helping manufacturers identify weak points in a vehicle’s design and materials. This ensures that cars remain reliable throughout their lifespan.

Vehicles serve as a constant companion in our daily lives, enduring a multitude of challenges and diverse terrains. From navigating pothole-ridden urban streets to traversing rugged off-road trails, from enduring sweltering summers to braving freezing winters, these machines must stand up to the test of time and environmental adversities. Durability testing emerges as the crucial bedrock upon which vehicular reliability is built, offering several pivotal benefits for both manufacturers and consumers:

Enhanced Safety: Beyond merely identifying weak points, durability testing actively contributes to the enhancement of vehicle safety. It goes hand in hand with crash testing and structural integrity assessments to ensure that cars are not only reliable but also capable of protecting passengers in the event of accidents or collisions.

Longevity and Sustainability: In an era where sustainability and longevity are highly valued, durability testing plays a pivotal role in extending a vehicle’s operational life. By subjecting vehicles to rigorous tests that mimic real-world wear and tear, manufacturers can produce cars that remain dependable for a more extended period. This aligns with consumer preferences for vehicles that offer value for money and environmental sustainability.

Optimized Maintenance: Manufacturers can use the insights gained from durability testing to create optimized maintenance schedules. This, in turn, benefits vehicle owners by reducing unforeseen breakdowns and repair expenses. As a result, drivers experience a smoother and more predictable ownership journey.

Extreme Conditions Preparedness: Durability testing extends far beyond ordinary road conditions. It takes vehicles to the extremes, evaluating their performance in extreme cold, high temperatures, high altitudes, and corrosive environments. This extensive testing ensures that cars are ready to perform reliably in any climate or geography, providing consumers with peace of mind.

Consumer Trust: The knowledge that extensive durability testing has been conducted instills trust and confidence in consumers. Knowing that a vehicle has been rigorously tested under various conditions gives buyers assurance in their investment and fosters brand loyalty.

Cost-Effective Quality Assurance: While durability testing involves substantial investment, it is a cost-effective quality assurance measure. It helps manufacturers address design and material flaws early in the development process, preventing costly recalls and warranty claims down the line. This, in turn, protects a company’s reputation and financial health.

Continuous Improvement: Durability testing promotes a culture of continuous improvement within the automotive industry. As new materials, technologies, and design concepts emerge, they are subjected to rigorous testing, driving innovation and advancements in vehicle durability and performance.

Global Accessibility: Vehicles must cater to a global market with diverse climates and conditions. Durability testing ensures that cars are built to meet the challenges of different regions and markets, facilitating global accessibility for manufacturers.

In conclusion, durability testing is the unsung hero of the automotive industry, ensuring that vehicles are not just reliable, but capable of withstanding the myriad challenges they encounter during their lifespans. It is a testament to the industry’s commitment to safety, sustainability, and the satisfaction of its customers, ultimately paving the way for more dependable and resilient vehicles on our roads.

You can also read more about this here: Analysis Engineer, Vehicle Engineering – Tesla Careers

Effective testing and simulation can lead to cost savings. By identifying design flaws or performance issues early in the development process, manufacturers can avoid expensive recalls and re-engineering efforts. This proactive approach ultimately reduces production costs.

The proactive approach of effective testing and simulation not only contributes to improved product quality but also yields substantial cost savings across various stages of the vehicle development process. Let’s delve deeper into the multifaceted benefits of early issue identification and its impact on cost efficiency:

Minimized Recall Expenses: Identifying design flaws or safety issues in the early stages of development can prevent potentially catastrophic scenarios later on. Recall campaigns, which can be astronomically expensive and damaging to a manufacturer’s reputation, are often triggered by safety concerns or performance failures. Effective testing and simulation help mitigate these risks by ensuring that critical flaws are addressed before vehicles reach consumers.

Streamlined Design Iterations: In the traditional product development cycle, design iterations can be time-consuming and costly. Testing and simulation enable engineers to virtually assess multiple design alternatives and configurations. This streamlined approach not only accelerates the design process but also reduces the need for physical prototypes, which can be expensive to manufacture and test.

Optimized Materials and Components: Comprehensive testing and simulation help manufacturers make informed decisions about materials and components. By simulating how different materials will perform under various conditions, engineers can select the most suitable and cost-effective options. This optimization not only reduces material costs but also contributes to vehicle durability and longevity.

Efficient Production Processes: Identifying potential manufacturing challenges early in the development process allows manufacturers to fine-tune production processes. This includes optimizing assembly procedures, reducing cycle times, and minimizing the risk of defects. As a result, production efficiency is enhanced, leading to lower labor costs and improved overall quality.

Reduction in Warranty Expenses: Early issue detection directly impacts warranty expenses. Vehicles that have undergone thorough testing and simulation are less likely to experience unexpected failures or breakdowns. Consequently, warranty claims and associated repair costs are significantly reduced, benefiting both manufacturers and consumers.

Enhanced Supplier Relationships: Collaboration with suppliers is a critical aspect of automotive manufacturing. By sharing simulation data and insights with suppliers, manufacturers can work together to identify potential issues and implement cost-effective solutions. This collaborative approach fosters stronger supplier relationships and promotes cost-saving initiatives throughout the supply chain.

Competitive Pricing: Cost savings achieved through effective testing and simulation can translate into competitive pricing for consumers. Automakers can pass on some of these savings in the form of lower vehicle prices, making their products more attractive in the market. This, in turn, can lead to increased sales and market share.

Long-Term Cost Benefits: While there may be initial investments in testing and simulation tools and expertise, the long-term cost benefits far outweigh these expenses. By consistently identifying and addressing issues early, manufacturers create a culture of quality and efficiency that permeates their entire organization.

In conclusion, effective testing and simulation methods are invaluable assets in the automotive industry, offering a range of benefits that extend well beyond product development. They serve as proactive cost-saving measures, fostering higher quality, improved safety, and enhanced efficiency. By investing in comprehensive testing and simulation throughout the vehicle development process, manufacturers not only protect their bottom line but also deliver higher value and satisfaction to consumers in an increasingly competitive market. This approach is a win-win, ensuring that vehicles are not only safer and more reliable but also more affordable in the long run.

Additionally, you can find further information on this topic by visiting this page: GAO-20-195G, Cost Estimating and Assessment Guide: Best …

Crash tests simulate real-world collisions and assess the structural integrity of vehicles, as well as the safety of occupants. These tests help manufacturers design vehicles that can protect passengers in accidents.

Crash tests are an indispensable component of vehicle safety evaluation, serving as a critical bridge between engineering and real-world safety outcomes. Beyond their role in assessing structural integrity and occupant safety, they represent a cornerstone of the automotive industry’s commitment to enhancing safety standards and reducing the severity of accidents. Here’s a more comprehensive exploration of how crash tests benefit vehicle design and passenger protection:

Comprehensive Safety Evaluation: Crash tests are not limited to evaluating a vehicle’s structural integrity; they encompass a wide array of safety aspects. These tests examine the performance of safety features such as airbags, seat belts, crumple zones, and anti-lock braking systems (ABS). By providing a holistic assessment of safety systems, crash tests ensure that vehicles are equipped to protect passengers from a variety of potential hazards.

Real-world Scenario Replication: Crash tests are meticulously designed to replicate real-world accident scenarios. Whether it’s a frontal collision, side impact, rollover, or rear-end collision, each test scenario provides invaluable insights into how a vehicle performs when subjected to specific types of accidents. Manufacturers use this data to make necessary design adjustments and enhance the overall safety of their vehicles.

Benchmarking and Continuous Improvement: Crash test results serve as benchmarks for manufacturers to evaluate their vehicles’ safety performance relative to industry standards and competitors. This comparative analysis motivates continual improvement in vehicle safety features and design, fostering a culture of innovation and raising the bar for safety across the industry.

Regulatory Compliance: Regulatory agencies worldwide, such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP), mandate specific safety standards and conduct their own crash tests. Manufacturers must meet these standards to sell vehicles in these markets. Crash tests ensure regulatory compliance and help manufacturers avoid costly recalls or fines.

Consumer Confidence: The results of crash tests are often publicized and made available to consumers through safety ratings and reports. This transparency allows consumers to make informed choices when selecting a vehicle, considering not only performance in routine driving but also safety in accident scenarios. High safety ratings instill confidence in a vehicle’s ability to protect its occupants.

Innovations in Vehicle Design: Crash test outcomes inspire innovations in vehicle design. Manufacturers continuously invest in research and development to enhance vehicle structures, materials, and safety features. As a result, modern vehicles are equipped with advanced safety technologies, including pedestrian detection, autonomous emergency braking, and advanced driver assistance systems (ADAS).

Crash Compatibility: Crash tests evaluate not only how a vehicle performs when colliding with a barrier but also its compatibility with other vehicles on the road. This aspect is crucial for reducing injuries in multi-vehicle accidents. Crash compatibility studies inform manufacturers about potential risks and guide design modifications to mitigate them.

Occupant Protection and Injury Prevention: Crash tests assess the effectiveness of various safety measures in preventing injuries to vehicle occupants. This includes evaluating the performance of restraint systems, seat structures, and headrests. The data generated from these tests inform manufacturers about areas for improvement in passenger safety.

Future-focused Safety: As vehicles evolve, so do crash test methodologies. Crash tests now consider the safety implications of emerging technologies such as electric powertrains, autonomous driving systems, and vehicle-to-everything (V2X) communication. Manufacturers use this information to ensure that safety remains a priority in future vehicle development.

In summary, crash tests play a pivotal role in the automotive industry’s mission to design vehicles that prioritize passenger safety. These tests provide comprehensive insights into a vehicle’s performance in real-world accident scenarios, drive continuous improvement in safety features and design, and inspire innovations that save lives. As technology and safety standards continue to advance, crash testing remains a cornerstone of the industry’s commitment to protecting vehicle occupants and reducing the impact of accidents on the road.

To expand your knowledge on this subject, make sure to read on at this location: The Road to Virtual Safety Simulations and Crash Testing | SAP …

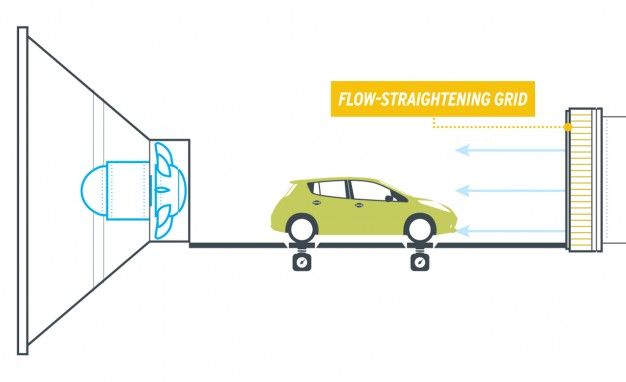

Wind tunnel testing evaluates a vehicle’s aerodynamics, helping reduce drag and improve fuel efficiency. It is particularly important for high-speed or electric vehicles.

Wind tunnel testing stands as a pivotal step in the development of modern vehicles, enabling engineers to unlock the full potential of aerodynamics. Beyond reducing drag and enhancing fuel efficiency, this process plays a multifaceted role in shaping the performance and sustainability of a wide range of vehicles.

Optimizing Design for Reduced Drag: Wind tunnel testing allows engineers to meticulously analyze how air flows around a vehicle, providing invaluable insights into its aerodynamic performance. By fine-tuning the vehicle’s design, they can strategically reduce turbulence and minimize drag, thus improving its overall efficiency. This optimization is not limited to high-speed sports cars; it extends to everyday vehicles, where even minor improvements in aerodynamics can lead to substantial fuel savings over time.

High-Speed Vehicles: For high-speed vehicles, such as sports cars or supercars, wind tunnel testing is particularly crucial. These vehicles operate in an environment where aerodynamic efficiency is paramount. Every curve, contour, and spoiler is meticulously crafted to generate downforce, enhance stability, and ensure peak performance. Wind tunnel testing helps engineers strike the delicate balance between speed and control, making these vehicles a symphony of form and function.

Electric Vehicle Advancements: In the realm of electric vehicles (EVs), wind tunnel testing takes on added significance. The efficiency of an EV’s aerodynamics directly impacts its range, as lower drag coefficients lead to less energy consumption during highway driving. As the world embraces sustainable transportation solutions, optimizing the aerodynamics of EVs is pivotal for extending their range and making them more appealing to consumers.

Evolving Sustainability: Beyond the immediate benefits for vehicle performance, wind tunnel testing aligns with the broader goals of sustainability. Reducing aerodynamic drag directly translates to lower fuel consumption and reduced emissions. In an era where environmental concerns are at the forefront, this aspect of aerodynamics becomes a powerful tool in mitigating the carbon footprint of the automotive industry.

From Concept to Reality: Wind tunnel testing bridges the gap between conceptual design and real-world performance. It allows engineers to validate their ideas and make informed decisions about which design elements should be retained or adjusted. This iterative process is essential for creating vehicles that not only look impressive on paper but also deliver tangible benefits on the road.

In summary, wind tunnel testing is a cornerstone of vehicle development, impacting everything from fuel efficiency and high-speed performance to the range and sustainability of electric vehicles. As automotive engineering continues to advance, the quest for superior aerodynamics remains integral to creating vehicles that are not only powerful and efficient but also environmentally responsible.

You can also read more about this here: The effect of ground simulation on the flow around vehicles in wind …

Emission testing measures pollutants in a vehicle’s exhaust, ensuring compliance with environmental regulations. It plays a crucial role in the development of cleaner, more fuel-efficient engines.

Emission testing measures pollutants in a vehicle’s exhaust, ensuring compliance with environmental regulations. It plays a crucial role in the development of cleaner, more fuel-efficient engines, contributing to both a healthier environment and a more sustainable future of transportation.

Environmental Preservation: Emission testing is not just about regulatory compliance; it’s about safeguarding the environment. By monitoring and controlling the release of harmful pollutants like carbon monoxide, nitrogen oxides, and particulate matter, emission testing helps mitigate the adverse effects of air pollution, such as smog formation and respiratory illnesses. This preservation of air quality benefits both urban and rural areas, enhancing the overall quality of life.

Fuel Efficiency and Engine Performance: To pass emission tests, vehicles must operate efficiently. Automakers invest in advanced engine technologies and control systems to reduce emissions while maximizing fuel efficiency. This pursuit of cleaner combustion processes often leads to innovations that improve engine performance and power output, benefiting consumers and the environment simultaneously.

Greenhouse Gas Reduction: Emission testing is not limited to conventional pollutants; it also addresses greenhouse gases like carbon dioxide (CO2). As concerns about climate change mount, emission testing becomes increasingly crucial in controlling and reducing CO2 emissions from vehicles. This aligns with global efforts to mitigate the effects of climate change by curbing the transportation sector’s carbon footprint.

Innovation and Regulation: Emission testing acts as a driving force behind innovation in automotive engineering. Stricter emission standards prompt automakers to explore alternative powertrains, such as hybrids and electric vehicles, as well as alternative fuels like hydrogen and biofuels. These innovations are transforming the industry and promoting a more diversified and sustainable transportation ecosystem.

Consumer Awareness: Emission testing results are often disclosed to consumers, allowing them to make informed choices about the environmental impact of their vehicles. This awareness has led to increased demand for cleaner, eco-friendly vehicles, pushing automakers to prioritize green technologies in their product portfolios.

Global Collaboration: Emission standards and testing procedures are often harmonized on a global scale. This promotes consistency in vehicle emissions across international markets and encourages collaboration between governments, automakers, and environmental organizations to reduce the environmental impact of transportation on a global scale.

Retrofit Solutions: Emission testing has led to the development of retrofit solutions for older, high-emission vehicles. Technologies like catalytic converters and diesel particulate filters can be added to existing vehicles, significantly reducing their harmful emissions and extending their service life.

In summary, emission testing is not merely a regulatory requirement; it’s a cornerstone of environmental stewardship and technological progress in the automotive industry. By continuously raising the bar for emissions standards, society is driving automakers to innovate, creating vehicles that are not only cleaner but also more efficient and technologically advanced. This dynamic interplay between regulation, innovation, and environmental awareness is steering us toward a greener and more sustainable future of transportation.

If you’d like to dive deeper into this subject, there’s more to discover on this page: Exhaust emission testing methods – BOSMAL’s legislative and …

Durability tests subject vehicles to harsh conditions to assess their long-term reliability. This includes testing components like engines, suspensions, and transmissions for wear and tear.

Durability testing stands as a crucial phase in the development of any vehicle, where resilience and long-term reliability are put to the ultimate test. It goes beyond assessing initial performance and delves into the realm of long-term endurance, ensuring that vehicles can withstand the rigors of daily use and even extreme conditions. Here’s an in-depth look at the significance and methodologies behind durability testing:

Real-World Simulation: Durability testing aims to simulate the real-world conditions that vehicles will encounter over their operational lifespan. This includes subjecting them to a range of environmental factors, such as temperature extremes, humidity, and corrosive agents. These tests expose any vulnerabilities to degradation, rust, or other forms of wear and tear.

Endurance on the Road: To gauge long-term reliability, vehicles are often subjected to extended road tests. These tests might involve driving on rough terrain, pothole-riddled roads, or gravel to evaluate suspension components, shock absorbers, and chassis integrity. Such trials help identify potential weak points and areas that need reinforcement.

High-Mileage Tests: Some durability tests aim to accumulate high mileage on vehicles in a relatively short time frame. This involves running vehicles continuously on test tracks or closed courses to replicate years of real-world driving in a compressed timeframe. This helps assess engine longevity, transmission performance, and overall vehicle robustness.

Vibration and Shock Testing: Durability tests include exposing vehicles to intense vibrations and shocks. These tests reveal how well components and fasteners hold up under constant oscillations, ensuring that nothing comes loose or fails prematurely.

Salt Spray and Corrosion Resistance: In regions with harsh winter climates or coastal areas with salty air, corrosion can be a significant concern. Durability testing often includes subjecting vehicles to salt spray chambers to assess their corrosion resistance, particularly in critical areas like the underbody and chassis.

Powertrain Reliability: Testing powertrain components, including engines and transmissions, under extreme conditions is essential. Continuous operation at high RPMs, towing heavy loads, and cycling through countless start-stop cycles help determine the long-term reliability of these critical systems.

Component Wear and Tear: Durability testing evaluates how various vehicle components wear over time. This includes the wear and tear of brake pads, tires, and suspension bushings. It helps engineers understand maintenance needs and plan for component replacements.

Electronic Systems: Modern vehicles are equipped with complex electronic systems. Durability tests assess the resilience of these systems to factors like extreme temperatures, voltage fluctuations, and electromagnetic interference to ensure uninterrupted functionality.

Lifecycle Predictions: Data collected from durability testing is invaluable in predicting a vehicle’s lifecycle and determining maintenance intervals. Manufacturers can provide recommendations for maintenance schedules and parts replacement based on real-world performance data.

Quality Assurance: Durability testing is not solely about identifying weaknesses; it’s also a quality assurance measure. Vehicles that pass these rigorous tests are a testament to their engineering excellence and serve as a guarantee of reliability to consumers.

In sum, durability testing represents a rigorous and exhaustive evaluation of a vehicle’s ability to withstand the trials of time and usage. It is an indispensable step in the development process, ensuring that vehicles not only perform well when they leave the showroom floor but continue to do so for years, thereby earning the trust and satisfaction of consumers around the world.

For additional details, consider exploring the related content available here Efficiently Optimize Vehicle Durability With Virtual Tests Using …

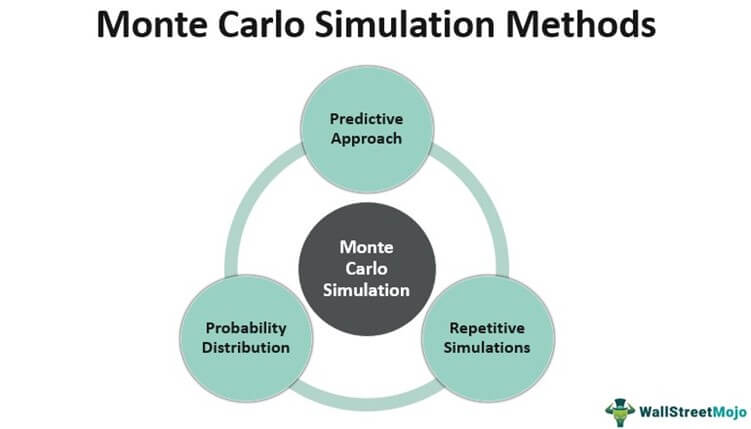

Virtual simulations use computer models to predict how a vehicle will perform in various scenarios. This includes crash simulations, computational fluid dynamics (CFD) for aerodynamics, and finite element analysis (FEA) for structural integrity.

Virtual simulations represent a cornerstone of modern vehicle development, offering engineers an invaluable tool to meticulously analyze and optimize every facet of a vehicle’s performance and safety. Here are some key aspects and advancements in the realm of virtual simulations:

Crash Simulations: In the quest for safer vehicles, crash simulations have become an essential component of virtual testing. High-fidelity computer models can accurately predict how a vehicle will perform in various collision scenarios, helping engineers design crumple zones, airbag deployment systems, and vehicle structures that maximize occupant protection.

Occupant Safety: Beyond predicting the vehicle’s response to crashes, virtual simulations also delve into occupant safety. Advanced modeling allows engineers to assess the behavior of crash test dummies during impacts, helping refine seatbelt designs, airbag deployment algorithms, and even the placement of child safety seats to enhance protection for all occupants.

Pedestrian Safety: Virtual simulations extend their reach to pedestrian safety as well. By modeling the interaction between vehicles and pedestrians, engineers can design front-end structures and hood designs that mitigate injury in the event of a collision with a pedestrian.

Aerodynamic Optimization: Computational fluid dynamics (CFD) simulations enable engineers to fine-tune a vehicle’s aerodynamics. Virtual wind tunnel tests provide insights into how airflow interacts with the vehicle’s shape, allowing for the optimization of spoilers, diffusers, and underbody panels to reduce drag, enhance fuel efficiency, and improve stability at high speeds.

Structural Integrity: Finite element analysis (FEA) is instrumental in ensuring a vehicle’s structural integrity. Virtual simulations assess how different materials and designs will withstand various loads, helping engineers select the right materials and reinforcement points to create a robust and lightweight structure.

Material Selection: Simulations assist in the selection of materials for various vehicle components. Engineers can predict how different materials, such as advanced alloys or composites, will perform under stress, allowing for the optimization of weight, strength, and durability.

Noise, Vibration, and Harshness (NVH): Virtual simulations also delve into NVH characteristics, helping engineers predict and reduce unwanted noise, vibrations, and harshness in the cabin. This ensures a quieter and more comfortable driving experience.

Fuel Efficiency and Emissions: Predictive modeling aids in optimizing powertrain efficiency. Virtual simulations can assess the performance of engines and transmissions under different conditions, helping to fine-tune fuel injection, combustion, and exhaust systems to improve fuel efficiency and reduce emissions.

Tire Performance: Simulation tools are used to evaluate tire performance under various road conditions. This assists in designing tires that provide optimal grip, handling, and longevity, which are crucial for both safety and performance.

Customization and Personalization: Virtual simulations are increasingly used to assess vehicle customization options. Customers can explore how different configurations, such as wheel choices or suspension settings, will impact vehicle performance and aesthetics before making their selections.

Time and Cost Savings: Virtual simulations significantly reduce the need for physical prototypes and testing, saving both time and resources. Engineers can quickly iterate through design variations and assess their performance virtually, accelerating the development process.

In essence, virtual simulations are at the forefront of vehicle engineering, enabling manufacturers to deliver safer, more efficient, and better-performing vehicles. This technology-driven approach is essential not only for meeting evolving safety and environmental regulations but also for creating vehicles that meet the increasingly diverse and demanding needs of consumers worldwide.

For additional details, consider exploring the related content available here Research on a Simulation Method of the Millimeter Wave Radar …

Real-world testing involves driving vehicles in various conditions, such as extreme temperatures, heavy traffic, or off-road terrain. This provides valuable data on how vehicles perform in the environments they are intended for.

Real-world testing stands as a critical bridge between laboratory simulations and the actual performance of vehicles on the roads. It goes beyond controlled environments to offer invaluable insights into how vehicles behave in the complex, ever-changing conditions of the real world. Here’s a closer look at the significance and multifaceted nature of real-world testing:

Diverse Environmental Conditions: Real-world testing exposes vehicles to a wide range of environmental conditions. From scorching desert heat to freezing polar temperatures, vehicles are subjected to extreme climates, ensuring they can operate reliably and efficiently, regardless of where they are driven.

Traffic Dynamics: Heavy traffic and congested urban areas present unique challenges for vehicles. Real-world testing allows engineers to assess factors like stop-and-go driving, lane changes, and the ability to handle sudden braking situations. This data informs the development of advanced driver assistance systems (ADAS) and autonomous driving technologies.

Terrain Versatility: For vehicles designed for off-road or rugged terrain, real-world testing in challenging landscapes is indispensable. It assesses a vehicle’s ability to navigate uneven surfaces, rocky trails, and muddy roads, ensuring it can deliver performance where it matters most.

Durability and Longevity: Real-world testing plays a pivotal role in evaluating the durability and longevity of vehicles. It allows engineers to monitor wear and tear on components, including engines, transmissions, suspensions, and tires, under real-world usage conditions. This data informs maintenance schedules and design improvements to extend a vehicle’s lifespan.

Safety Assessments: Safety is paramount in vehicle design. Real-world testing enables the evaluation of safety features in actual driving scenarios. Crash tests, collision avoidance systems, and emergency response mechanisms are put to the test to ensure they provide optimal protection for occupants and pedestrians.

User Experience: Real-world testing provides valuable insights into the overall user experience. Factors like comfort, ergonomics, and user interface usability are assessed in real-world driving situations. This information guides refinements to make vehicles more user-friendly and enjoyable.

Efficiency Optimization: Analyzing vehicle performance in real-world conditions is instrumental in optimizing fuel efficiency and emissions. Engineers can fine-tune engine management systems and aerodynamics based on how vehicles behave on the road, contributing to eco-friendly and cost-effective transportation.

Testing Advanced Technologies: With the rise of electric vehicles (EVs) and autonomous driving, real-world testing is essential for validating these cutting-edge technologies. It verifies the practicality of electric powertrains, battery range, and the functionality of autonomous features in diverse driving scenarios.

Customer Feedback Integration: Real-world testing often incorporates feedback from consumers and professional test drivers. Their experiences provide a valuable reality check, helping manufacturers address real-world challenges and align their products with customer expectations.

In conclusion, real-world testing is an indispensable step in the development of safe, reliable, and efficient vehicles. It’s the proving ground where innovative technologies are validated, user experiences are refined, and vehicles are prepared to excel in the dynamic and unpredictable conditions of the road. As automotive technology continues to advance, real-world testing will remain a cornerstone of the industry’s commitment to delivering high-quality vehicles that meet the demands of today’s diverse and challenging driving environments.

To expand your knowledge on this subject, make sure to read on at this location: Formal Scenario-Based Testing of Autonomous Vehicles: From …

Conclusion

Vehicle testing and simulation methods are the unsung heroes of the automotive industry. They allow engineers and manufacturers to push the boundaries of safety, performance, and efficiency. These methods not only help meet regulatory requirements but also drive innovation and shape the future of mobility. As technology continues to advance, testing and simulation will remain essential tools in the ongoing quest to develop vehicles that are safer, more eco-friendly, and capable of meeting the ever-evolving needs of consumers. In the dynamic world of automotive engineering, testing and simulation are the driving forces behind progress and excellence.

Explore this link for a more extensive examination of the topic: What is Simulation? What Does it Mean? (Definition and Examples …

More links

Looking for more insights? You’ll find them right here in our extended coverage: Simulation methods supporting homologation of Electronic Stability …